SCREW & SMALL METAL FABRICATION INDUSTRY

Automatic feed systems

for welding studs

and flange nuts

JOEST delivers feeding technology to screw technology manufacturer.

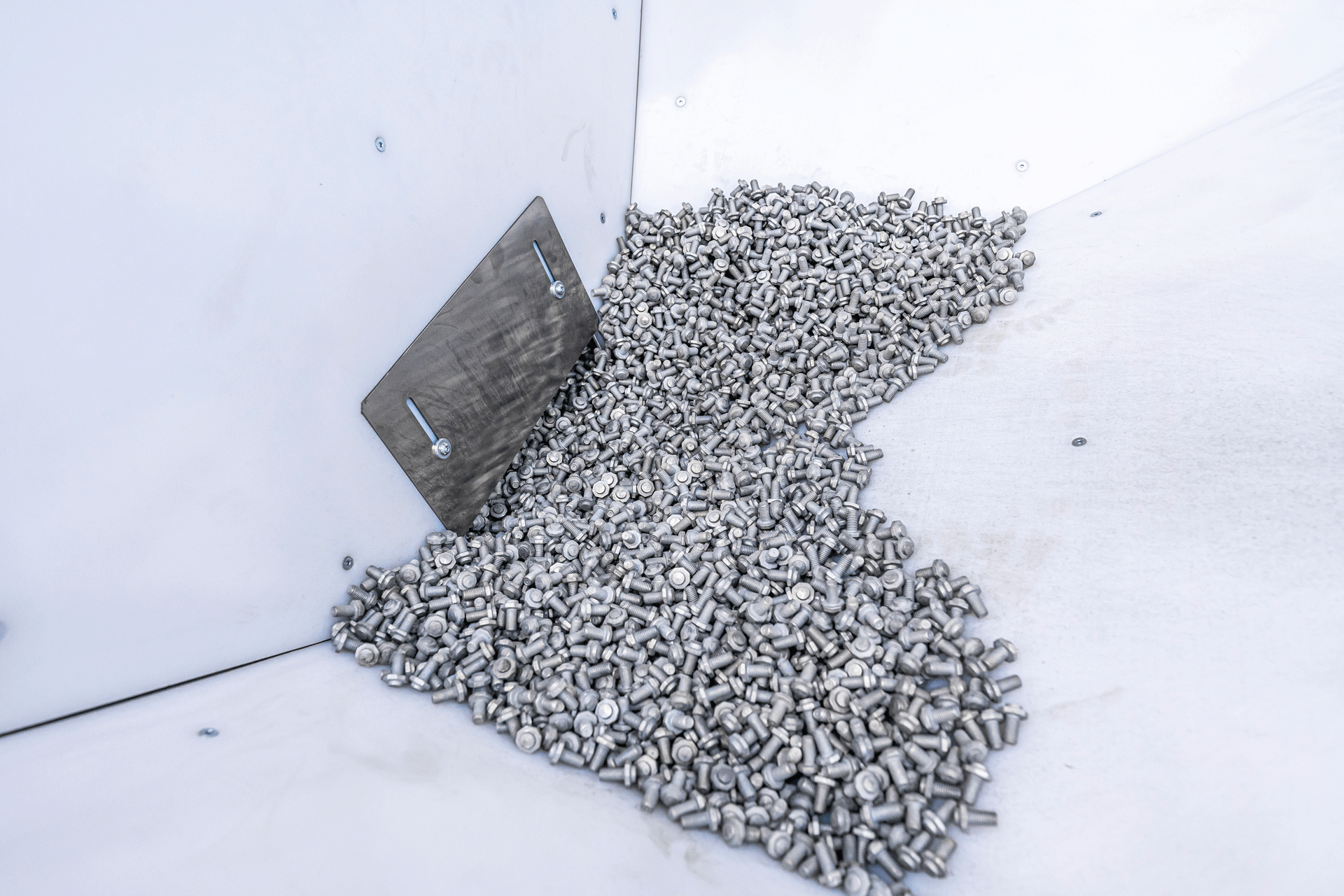

JOEST manufactured two automaticfeed systems to convey, sort and feedwelding studs and flange nuts. Thesystems are built up of an overheadconveyor with a link chain, a storage container, a linear feeder and a workpiece recirculation.

![]()

The workpieces are provided manually in a storage container with an effective volume of 320 liters. The container has a steel design and is lined with PU plates. It also features a filling level indicator. The parts are presorted by workpiece specific carrier rails, conveyed upwards and fed into a linear feeder.

The linear feeder is equipped with two parallel sorting feeders. On these feed-ers, alignment mechanisms force the workpieces into the correct orientation. Excess or falsely orientated parts are rejected by the linear feeder and are recirculated to the storage container. The sorting feeders are equipped with pneumatic deflectors to prevent the magazine from overflowing and to control the feeding lane in case a screw is left out.

At the end of the linear feeder, the workpieces are fed into the existing processing machines in a defined position. The welding studs are discharged to the left and the flange nuts to the right.

After development and manufacturing, the feeding systems were delivered in the fourth quarter of this year. The project was completed to the full satisfaction of all parties and JOEST is looking forward to new exciting projects.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.