SECONDARY RAW MATERIALS - RECYCLING

J-Flow Air Separator

from JOEST

The new compact class for metal recycling.

What do you need to achieve higher precision and purity in metal recycling? With the innovation of the J-Flow by JOEST, the answer is simple: Not a lot. The new compact Air Separator proves that for simple applications, machine size and investment costs can be significantly reduced – increasing simplicity and efficiency in the process.

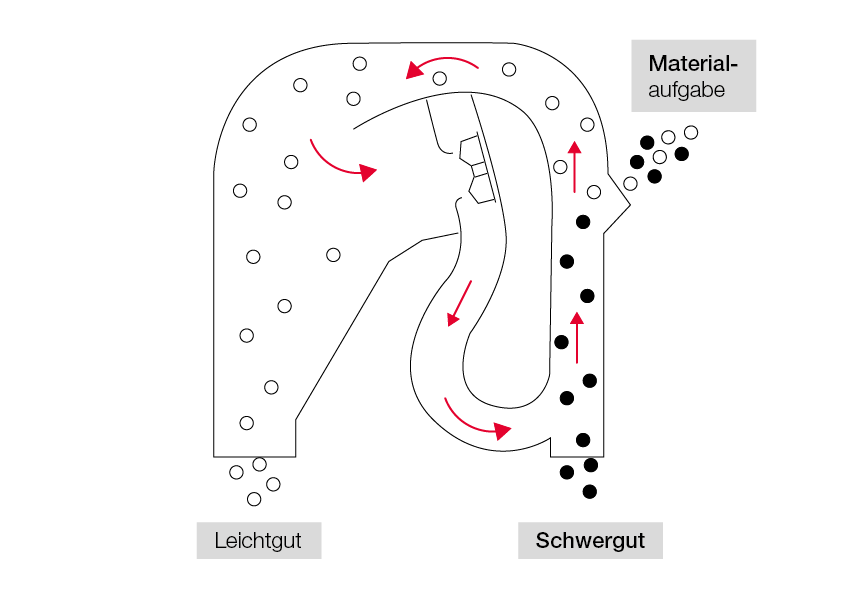

As a gravity separator, the J-Flow separates heavy parts from lightweight ones in an air stream. It is used for subsequent cleaning of metal fractions (ASR processing) to separate foils, fab-rics, lint, foam, Styrofoam and other light materials without losing to much metal. The operational grain sizes for the process are between 10 and 120 mm and long parts up to 300 mm.

Compact and inexpensive

One outstanding feature of this gravity separator is its small formfactor. The machine resembles a container that occupies a relatively small space. For comparison: A Zig-Zag Air Separator takes up 20 times the space of a J-Flow Air Separator at equal throughput rates. The J-Flow can therefore be easily integrated into existing plants. Installation and commissioning as well as operation control and cleaning are very simple. This lowers the costs from investment to operation.

“We set out to develop a compact Air Separator for simple applications, exemplary for a client of ours, one of the largest metal recycling companies in the US. To achieve this, we analyzed the entire process, as well as all critical parameters such as the air flow and pressure to develop intelligent new features.”, says Klaus Straetmanns, department manager of sorting technology in the JOEST group.

Development tailored to the operator

The sales department, head of engineering and the technical design team of JOEST in Duelmen used detailed demand profiles of operators, analyses and market studies to create a precise image of the status quo. In close collaboration with the JOEST colleagues in the US, they identified potential for optimization. The fans, the wear of machine components and the relation of air volume to pressure, which largely influences the sorting speed, were part of the team’s focus.

A focus on air flow –

radial fans as a solution

A key feature of the new J-Flow: It uses parallel radial fans instead of a crossflow fan like the ones used in most previous gravity separators. The advantage: More power to separate lightweight parts with a lower air volume – at a consistent separation result even for fluctuating amounts and sizes of material. The air volume can be continuously adjusted with a frequency converter depending on the amount of material.

Air flow simulations, readings and product tests in-house enabled further optimizations. For example, precisely aimed currents lead to less material accumulation, less wear and an improved precision, especially in the feed area. An adjustment of the air recirculation at the discharge end increases the availability of the machine. Furthermore, the J-Flow features many Airows that allow for better accessibility and insight into the process.

“We set out to develop a compact Air Separator for simple applications, exemplary for a client of ours, one of the largest metal recycling companies in the US.”

Klaus Straetmans, Technical Sales

The new generation of Air Separators

The J-Flow is turnkey ready for operation. As a compact class, it will initially be available in effective widths of 900 mm with two fans and 1800 mm with four fans for different throughput rates. Additional sizes are planned for the future.

The new Air Separator offers pinpoint performance for simple applications in metal recycling. It achieves 70 % of a JOEST Zig-Zag Air Separator’s precision at 50 % of its price – advantages that enable new applications for the J-Flow, such as alternative fuels.

AL SCRAP HEAVY

ICW HEAVY

AL SCRAP LIGHT

8-20 MM LIGHT

8-20 MM LIGHT

SHF 20-50 MM LIGHT

8-20 MM HEAVY

SHF 20-50 MM HEAVY

Sifting, Sorting, Separating

The Video of the J-Flow Air Separator

We need your consent to use the YouTube service!

More Information

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.