FORGING

100 m Conveying Cooler for forging party

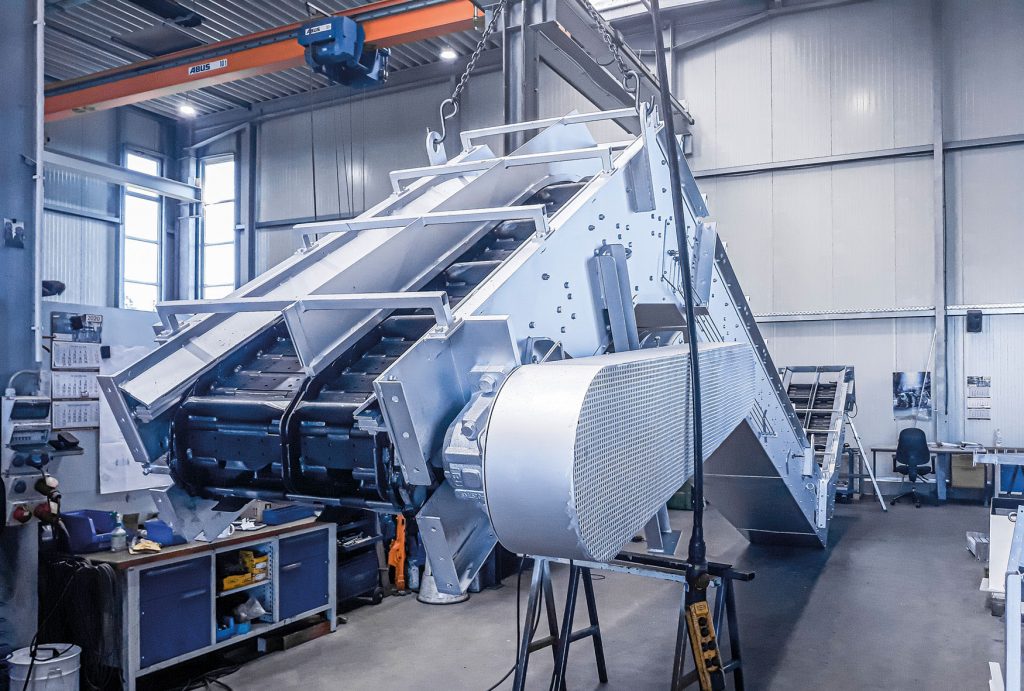

Dr. Goessling delivers Hinged Belt Conveyor and Wire Mesh Conveyor to client in Spain.

Dr. Goessling Maschinenfabrik GmbH delivered a conveying system specifically optimized for the client. Its main job is cooling, separating and transporting of 1,100°C parts and scrap. After the forging press, the parts are cooled and conveyed. During the process, the hot scraps are separated from the parts and disposed in according containers.

The 1,100°C hot forging parts that leave the forging press weigh up to 1,800 g each. They are placed on a welded Hinged Belt Conveyor that has been specially designed for the rough forging application and features a separation in the middle of the belt. At a rate of up to 100 parts per minute, the parts are conveyed on the right half and the scraps on the left.

To the left, the parts are then fed to a Wire Mesh Conveyor with cooling hoods and ventilators to generate the cooling air flow, where they are cooled. To the right, the scraps are fed to additional stamped Hinged Belt Conveyors. The stamped hinge elements are connected to the side rails, chains and each other by crossbars. The stamped Hinged Belt Conveyors are designed in a way that prevents parts from getting caught or pinched. Hence, the gap width is kept very small. All of the conveyors are equipped with special chains with manganese steel bocks that are suitable for forging applications.

During a prior project with Dr. Goessling in a parallel plant, the client has already had a positive experience and was convinced by the quality of the products. The client’s high satisfaction with Dr. Gössling’s technology and execution was once again the foundation for further cooperation. Commissioning of the plant with the Wire Mesh Conveyor and the welded and stamped Hinged Belt c Conveyors was successfully performed by the Dr. Gössling Team in September 2020.

The wide and extensive product spectrum of Dr. Goessling Maschinenfabrik GmbH was able to offer the perfect solution for this client. Dr. Goessling has the right products for your specific demands too, and is happy to consult!

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.