AUTOMOTIVE

63 meter Hinged Belt Conveyor for stamping scrap

Dr. Goessling delivers z-shaped conveyor for a plant in Poland.

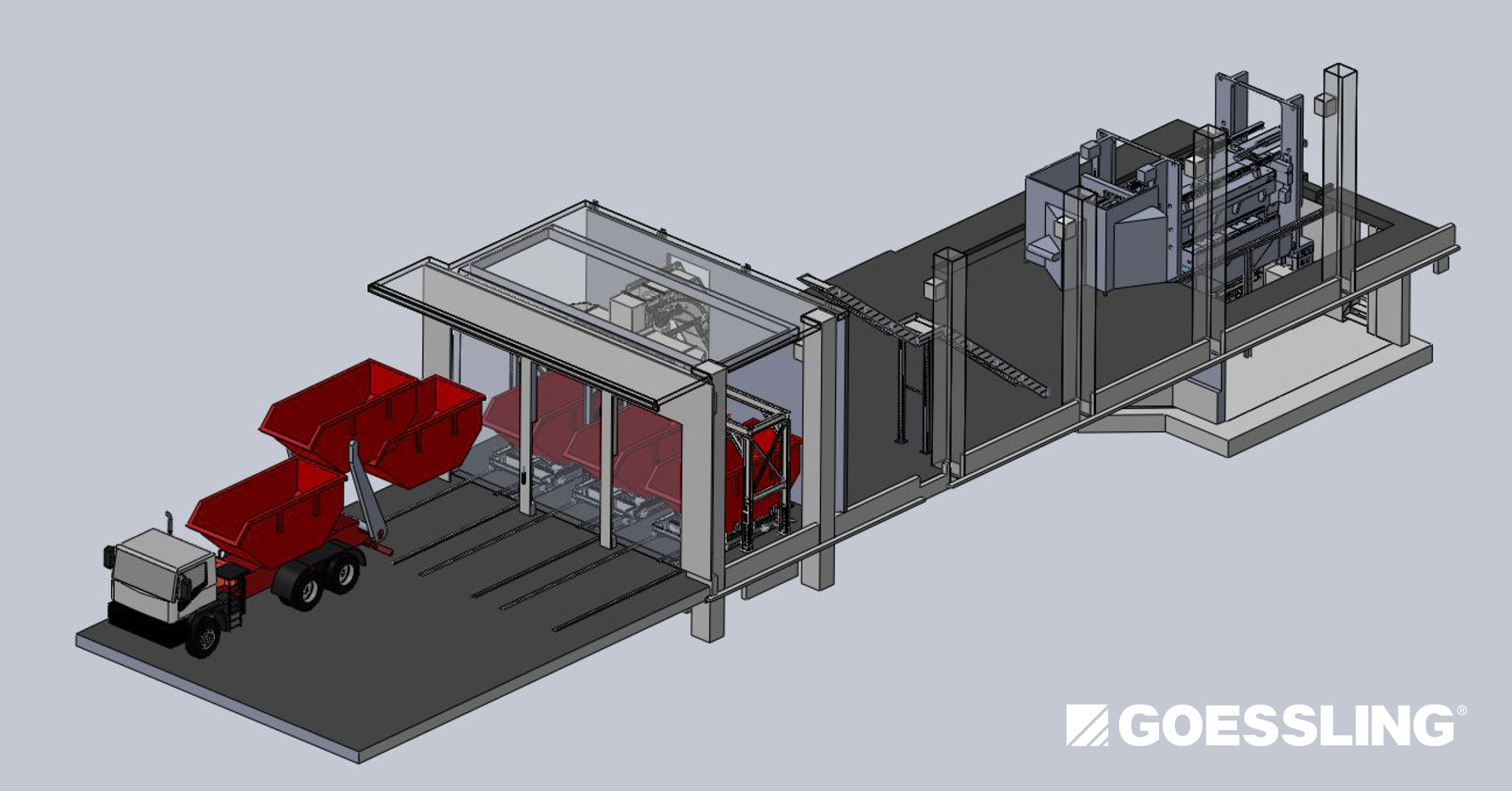

To replace the existing main conveyor in the client’s plant, Dr. Gössling Maschinenfabrik once again manufactured a conveyor to transport scrap from metal plates for the automobile industry. The model T150 Hinged Belt Conveyor was designed in a z-configuration and is operated in a plant in Poland.

A special demand by the client was to design the conveyor to transport scrap from a total of three press units, resulting in a throughput of up to 250 kg per minute. The conveyor is fed by upstream conveyors and slides with parts ranging from 3 to 700 mm in diameter and a thickness of 0.5 to 5 mm.

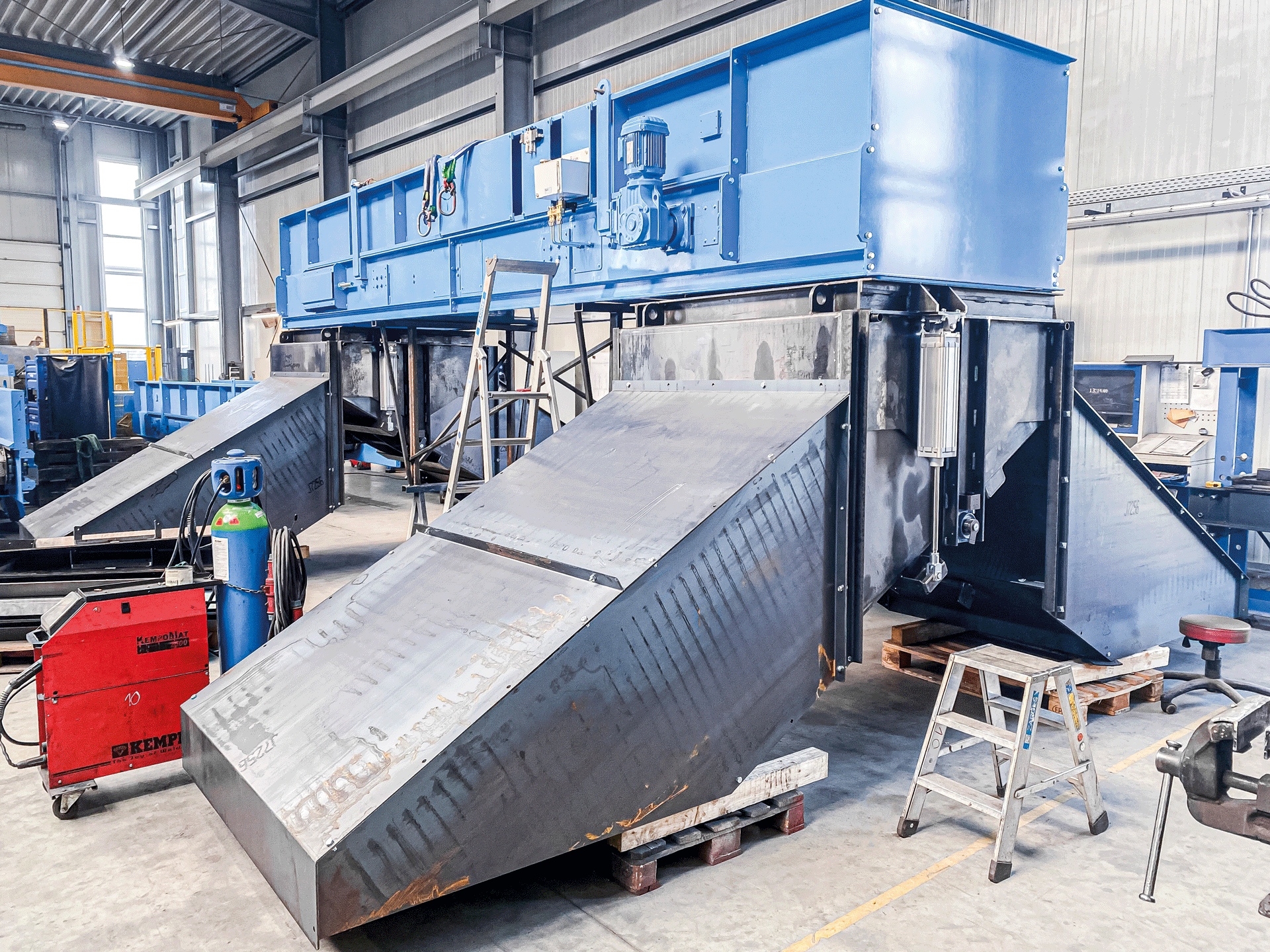

The Hinged Belt Conveyor has a total length of 63 meters designed in a z-shape. The total width of the conveyor is 1.4 m whilst the effective width is roughly one meter. The stamping scraps originate from three stamping units and are transported to the Goessling conveyor by other conveyors and slides. The conveying speed is 10 meters per minute. The charging end of the conveyor measures 46 meters in length. The conveyor then climbs at a 45° angle, covering 8 meters in height and finally extending another meter in horizontal direction at the discharge end. The conveyor feeds a reversible hopper-charging conveyor which then fills containers on-site via multiple slides. The conveying element in place here is a steel hinged belt. The belt and the carriers are design in a way that no scraps remain in the conveying structure. The structure is made of a sturdy steel plate construction with bolted side plates. The inner chain-guiding rails are made from hardened steel.

The Steel Hinged Belt is made up of stamped and rolled steel hinge segments with a burled surface. The hinge cranks are level, as opposed to those of our competitors. This reduces or even eliminates parts getting caught on the surface of the belt.

The burled variant prevents parts from sticking to the belt due to oil residue carried over from earlier processing. The lateral seal of the belt is designed specifically for metal stamping scraps. The seal is created by the PS (precision-)side rails of the steel hinged belt and the machined steel ledge that runs the length of the machine. It hermetically seals the circulating side rails and drive chains and also keeps the material from jamming in-between the belt and the frame. A big advantage of the system is its robust and low-maintenance technology. An oil pan that runs the length of the conveyor prevents leakage or a carryover of oil.

In addition to the advantages in technology, many years of prior cooperation with the client were deciding. The client’s plant already houses multiple Dr. Goessling conveyors, resulting in yet another choice for Dr. Goessling technology. Furthermore, Dr. Goessling convinced with many years of experience in this field, an outstanding service and highest quality standards.

Commissioning of the Hinged Belt Conveyor is scheduled for the end of this year and will be performed by Dr. Goessling. Thanks to good previous cooperation, Dr. Goessling is looking forward to finishing this project and to start future ones. The broad spectrum of products contains a solution for nearly every use case – including yours!

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.