MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.

FOOD INDUSTRY

Solution for Animal Feed Screening

In the animal feed industry, space and time are incredibly valuable. As global demand for high-quality animal feed continues to rise, production efficiency becomes a top priority.

Innovative conveying technology

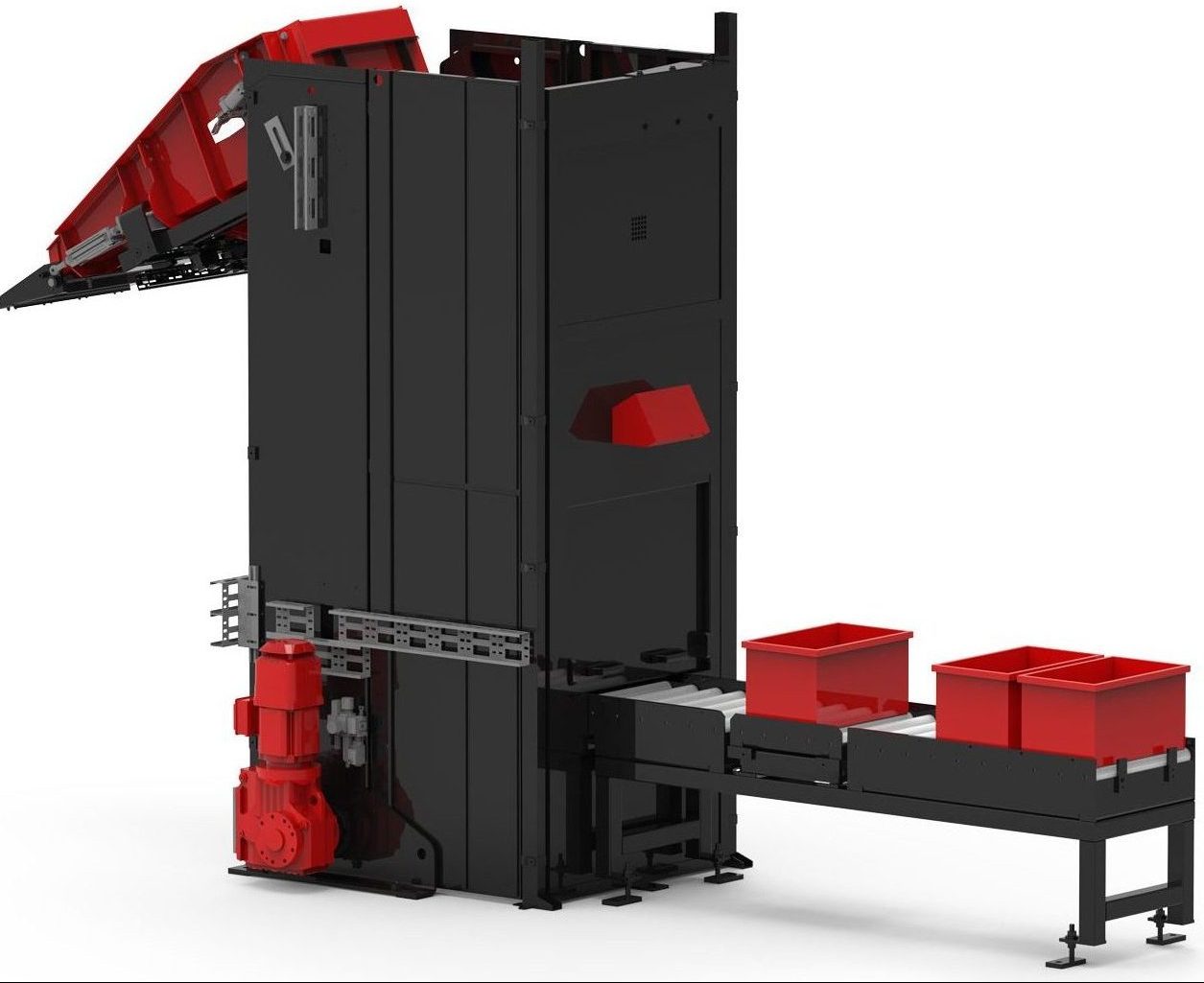

The long-standing partnership between JOEST and Driessen Food Extrusion has reached another milestone: the latest JOEST spiral elevator, specially developed for the vertical transport of freshly extruded, often sticky protein foods, was delivered to Deurne, the Netherlands, this week.

Vibrating Conveyor for Crystal Sugar

In February, JOEST secured an order for the delivery of a specialized 15-meter-long vibrating conveyor for a Serbian producer of sugar products. This machine is an integral part of the production process, conveying freshly centrifuged sugar with a throughput of up to 70 tons per hour at a moisture content of 0,2-0,4% and a product temperature of about 65°C.

Drying system for extruded proteins

The contract manufacturer Driessen Food Extrusion, based in Deurne in the Netherlands, processes mixed and powdered plant-based proteins into high-quality intermediates for the Food Industry.

To expand production, JOEST supplied a new drying system. It was designed in close collaboration with the client to meet the special requirements of a contract manufacturer in the Food Industry. The drying system, consisting of a Fluidized Bed Dryer with a process- , heating- , cooling- and exhaust air system as well as a Spiral Conveyor, was already installed this summer. The scope of delivery also included the system controls (control cabinet, control panel, etc.) from JOEST’s in-house Control Technology.

Lifting and Tipping Device with Dosing Feeder

In conventional applications, the Lifting and Tipping Device empties the bulk material in one gush, e.g. into downstream feeders. During the tipping process, blockages or damage to sensitive products can occur, due to the drop height. The latest Lifting and Tipping Devices can be fitted with an integrated dosing feeder. The feeder acts as a load pickup for the container. During the tipping process, the container empties its content slowly onto the feeder. Once the discharge position is reached, the vibratory drive is turned on to gently convey the bulk material into the downstream process. This type of feeding technique can be used for galvanized drums, sand blasting plants, packaging machines and many other applications.

Drying system for extruded proteins

The food manufacturer Driessen Food Extrusion located in Deurne, Netherlands processes mixed, powdered, plant-based proteins to high quality ingredients for the food industry. In order to modernize their production and increase productivity, Driessen Food Extrusion is planning to build a new production line. JOEST received a contract last month to provide large parts of this new production line. For the processing of extruded proteins and production high quality coatings, the #JOESTeam will design and manufacture a complete drying plant. The planned drying system consists of a Fluidized Bed Dryer with processing-, heating-, cooling- and used-air systems as well as a Spiral Conveyor. The system will be delivered in spring 2023.