At Blechexpo 2023, the JOEST group presented innovative solutions in sheet metal processing for the first time as an exhibitor at this industry-leading event with the GOESSLING brand.

STAMPING INDUSTRY

Gentle Feeding of Stamping Scrap

With reinforced belt and stamped hinges, the GOESSLING Hinge Belt Conveyor solves the previously existing problems in conveying stamping scrap at the customer’s site. To ensure that the parts no longer damage the belt and that a gentle feed is achieved, a special feed chute was designed. The conveyor rotates to both sides in order to feed and unload the parts in the best possible way. A swivel chute is also used at the front so that the rear containers are fed optimally.

Scrap disposal with three movable containers

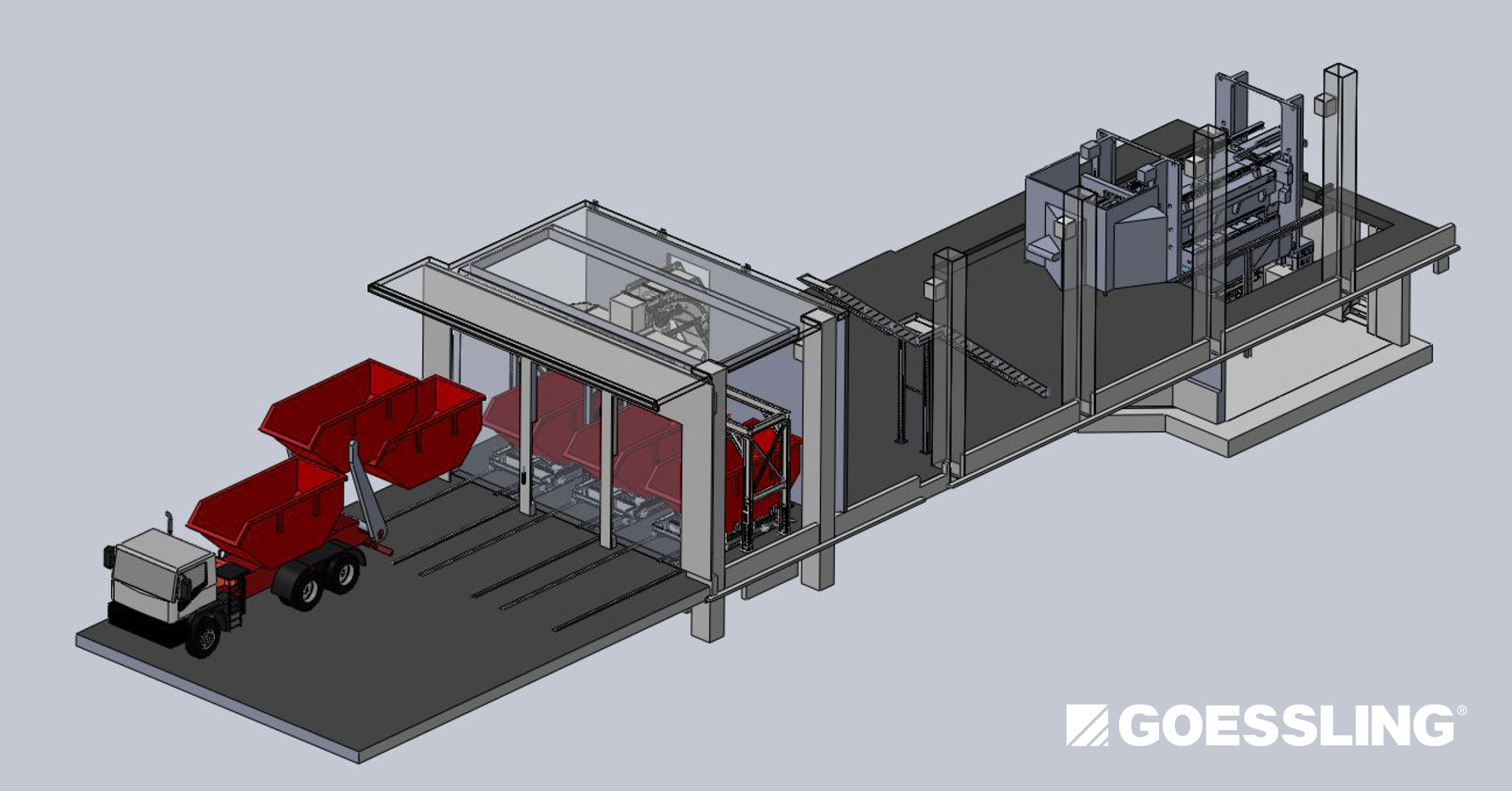

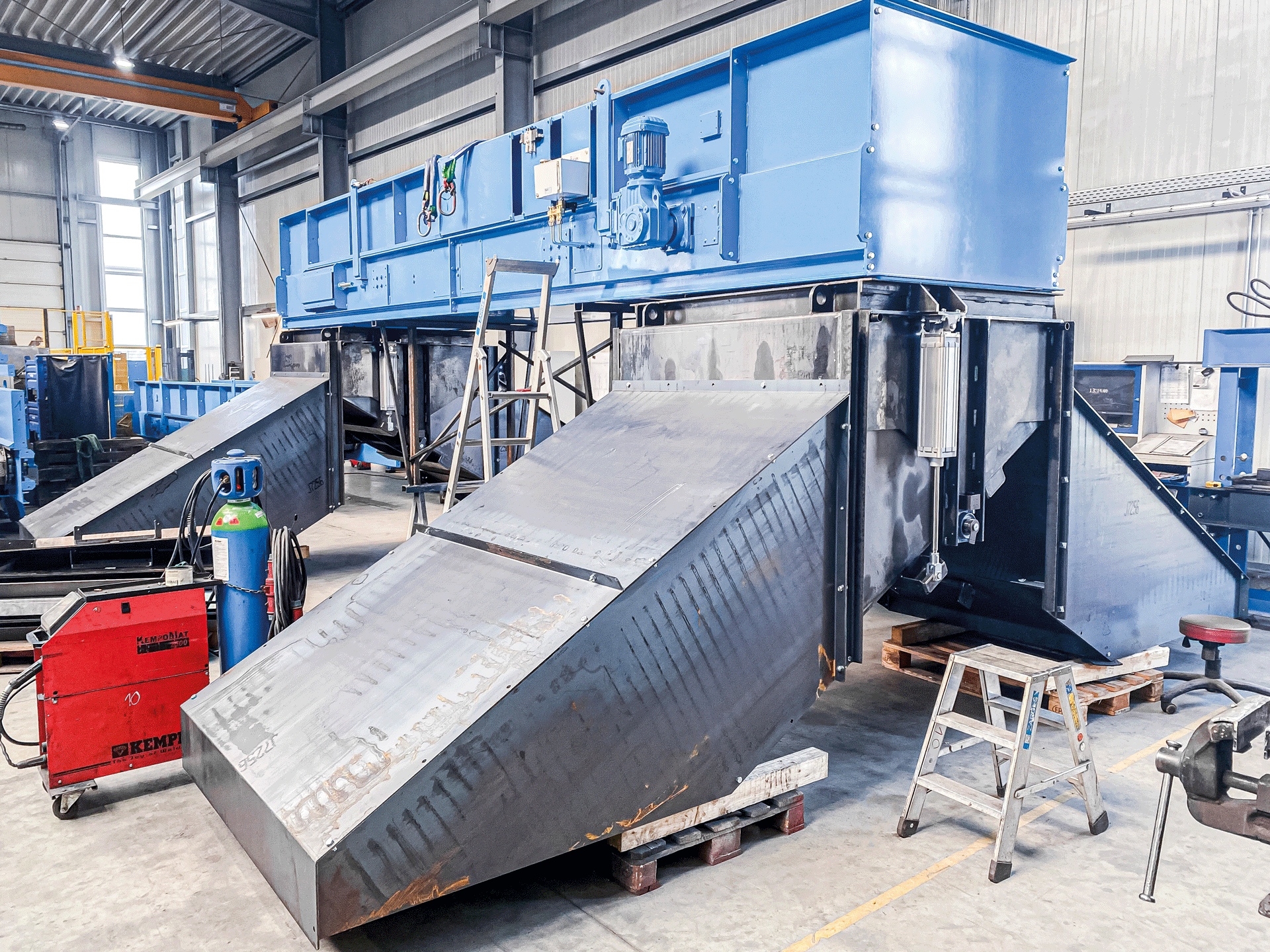

This year in September, the division GOESSLING delivered a customized conveying solution to a long-term client that once again relied on the high quality and positive user experience. When manufacturing chassis parts, stamping scrap occurs beneath the stamping press. These scrap parts must be disposed in containers. Using their experience in GOESSLING conveying technology, JOEST was able to offer the client a robust solution with excellent service. The special challenge of this project was that the stamping scrap is charged over a special chute system in the basement onto a Double-Z-Conveyor with an effective width of 625 mm. The scrap is then transferred on a reversible conveyor with the same effective width. At the the transitions, the reversible conveyor has pivoting chutes. The both pivoting slides enable the oily scraps to be distributed into three displaceable containers.

Disposing stamping scrap for the automotive industry

Once again, GOESSLING delivers its well proven conveying technology to Mexico for a client that already has multiple conveyors in operation around the world. For the disposal and separation of stamping scrap from manufacturing car bodies, the client relies on the quality and good experience with GOESSLING again. The objective here was to sort and dispose aluminum and steel scrap from a total of six steel presses. GOESSLING designed and manufactured eight Hinged Belt Conveyors with a combined length of 130 meters, a partition of 125 mm and an effective width of 1,025 mm. The sidewalls are specially designed for sheet metal scrap. The precision sidewalls of the steel hinged belt and the machined steel bar on the belt frame create a hermetical seal around the circulating curbs and drive chains of the conveyor. Additionally, the material is kept within the effective conveying width and material jams are prevented. The Hinged Belt Convey or is equipped with robust, low maintenance technology.

63 meter Hinged Belt Conveyor for stamping scrap

To replace the existing main conveyor in the client’s plant, Dr. Gössling Maschinenfabrik once again manufactured a conveyor to transport scrap from metal plates for the automobile industry…