CHEMICAL & PHARMA INDUSTRY

Clean transfer

of toxic bulk material

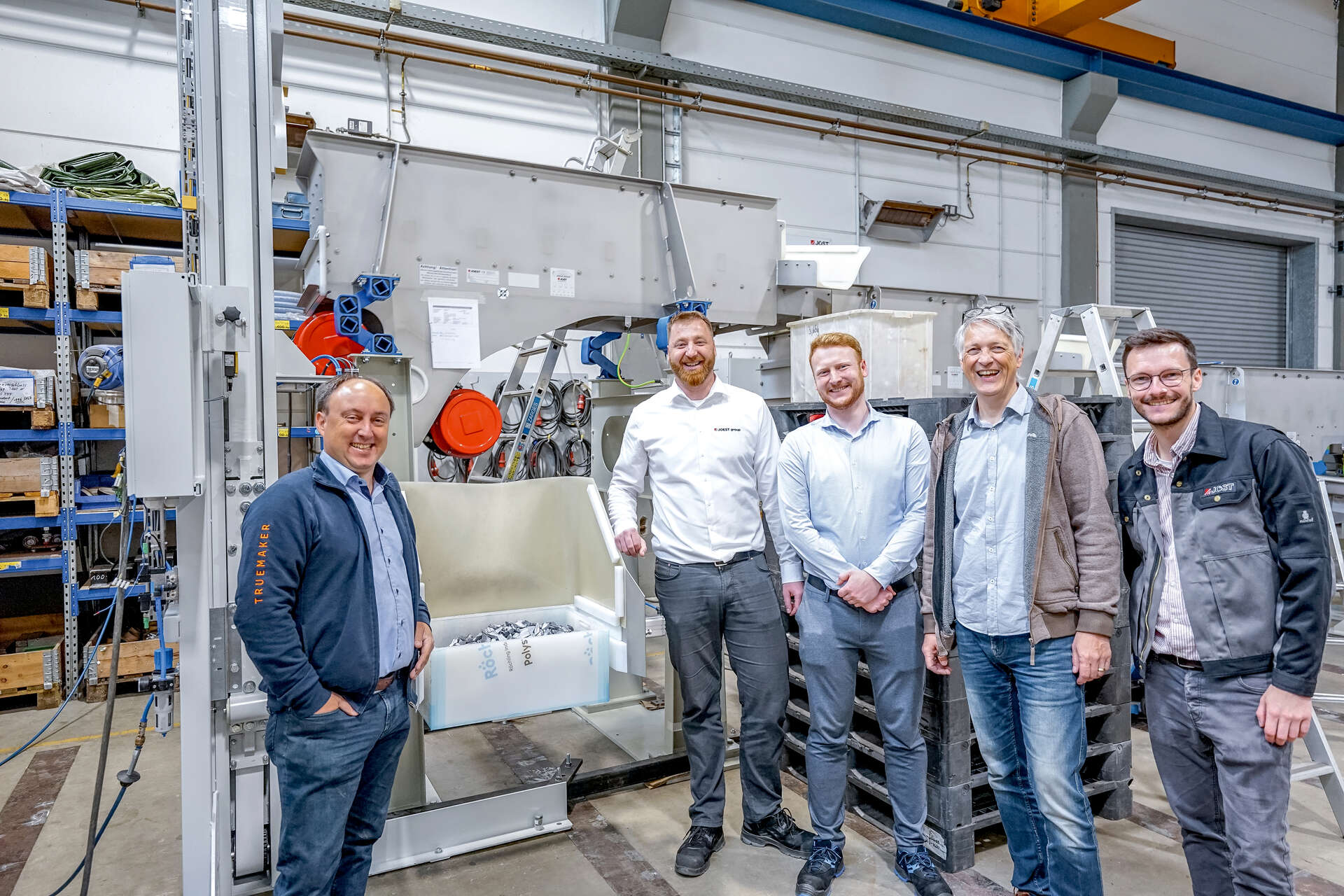

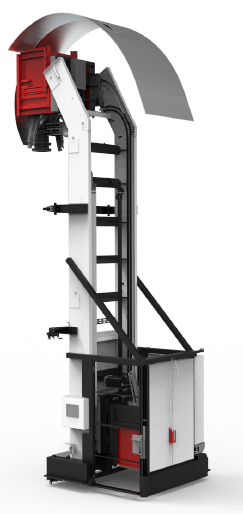

Two Lifting an Tipping Devices of the MD series with specially designed load handling devices.

![]()

JOEST delivered two Lifting and Tipping Devices from the MD series with specially designed load handling attachments to a client in Germany.

The machines run on rail tracks so they can easily change between different feeding points. This customized solution that is tailored to the client’s needs, meets highest standards in quality and reliability.

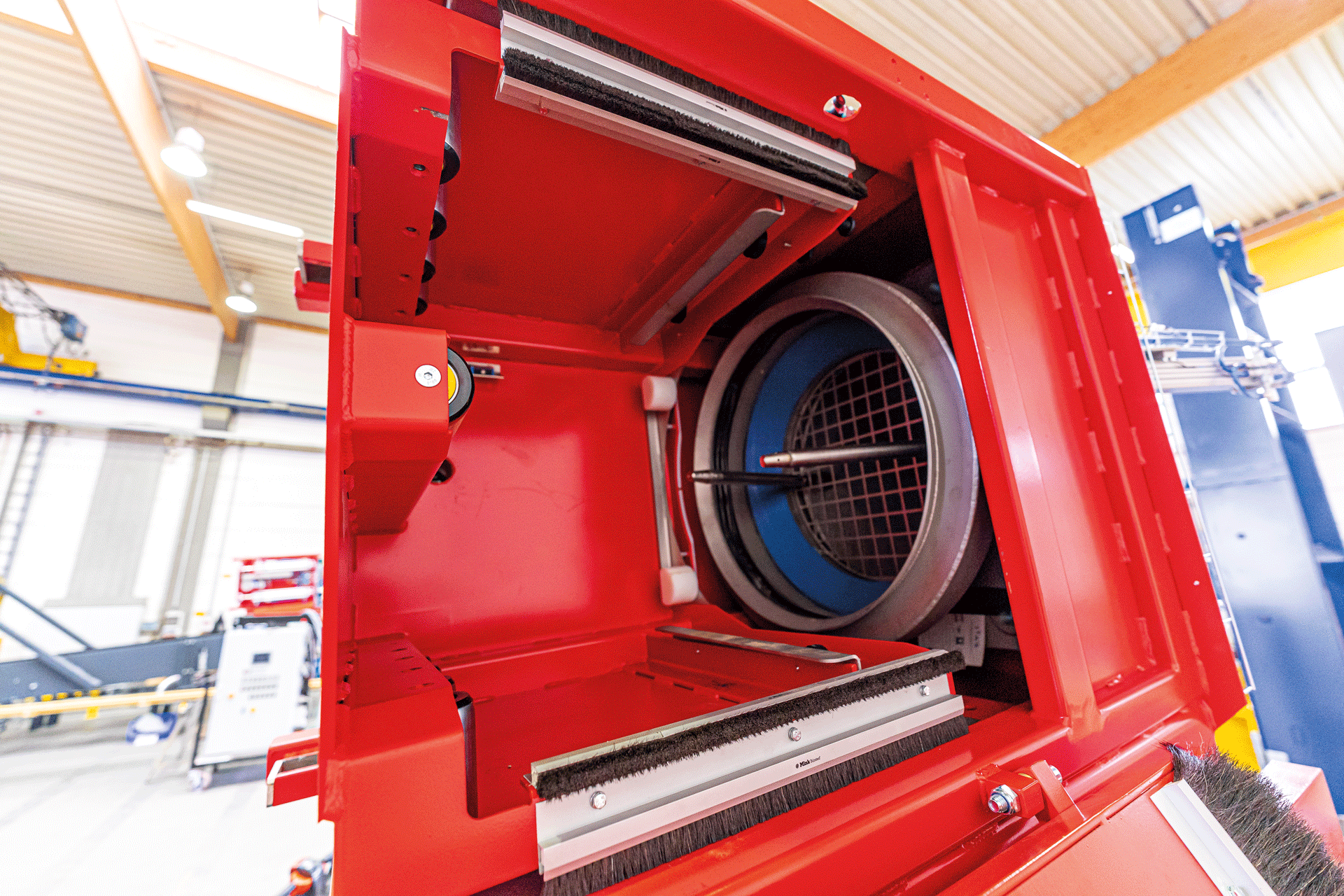

The client was searching for a solution to empty 200-liter steel barrels filled toxic bulk material of various grain sizes into a ball mill and a mixer. The main criterion was for the process to run as dust-free as possible. JOEST’s solution was to equip two Lifting and Tipping Devices from the series MD-6 with specially developed load handling attachments. The new design prevents most of the toxic dust from escaping the system. The entire load handling attachment is in a dust-tight enclosure and features a stainless-steel funnel with a pneumatic cover flap.

In the upper position where the barrel is emptied, and in the lower position where the barrel is exchanged, the machine is automatically connected to a dust extraction system.

The barrel is fixed to the system and an inflatable seal seals the barrel around the mantel. At the funnel exit and the feed points, there are automatic shut-off flaps and seals to prevent the material from leaving the system. Furthermore, the drive has a frequency control to adjust the speed of the machine. A shaker helps with the residual dis-

charge.

The low dust design of the load han-d-ling attachment provides operational safety in the workshop. Additionally, it prevents expensive loss of material. The angled head enables precise dock-ing and a safe material transfer to fol-lowing machines. Finally, multiple feed points are connected to the system via rail tracks.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.