METALLURGY

Conveyor plant for

quality inspection of

aluminum forging parts

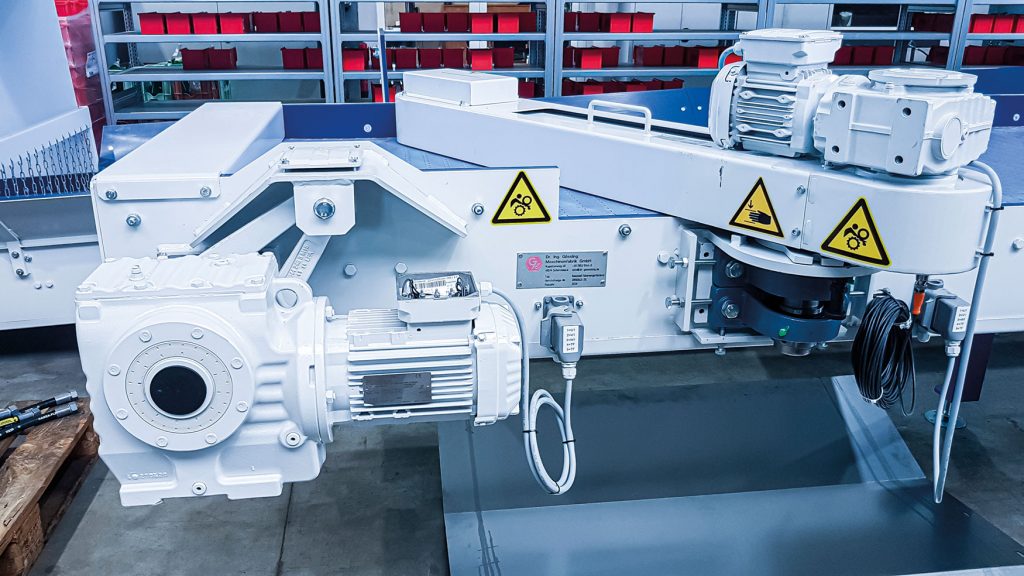

Dr. Goessling designs plastic Hinged Belt Conveyor with special discharge arms.

For a longstanding client with expertise in metal processing, Dr. Goessling Maschinenfabrik GmbH designed a special conveyor plant that allows for aluminum forging parts to be gently conveyed in a circuit. A particular discharge enables employees to manually perform quality inspections in full operation.

The client’s demands were to design a conveyor plant to gently transport aluminum forging parts. One specification was for the plastic Hinged Belt Conveyor to run in a circle and to discharge the parts at multiple arms for manual quality controls. Many years of experience in the development and manufacturing of conveyors of all sorts and the capability to incorporate individual client demands made Dr. Goessling the first choice.

The client’s demands were to design a conveyor plant to gently transport aluminum forging parts. One specification was for the plastic Hinged Belt Conveyor to run in a circle and to discharge the parts at multiple arms for manual quality controls. Many years of experience in the development and manufacturing of conveyors of all sorts and the capability to incorporate individual client demands made Dr. Goessling the first choice.

Four similar plants have already been delivered to the client. The good cooperation, service and quality of the Goessling machines were once again the reason behind the decision to build another conveyor together. Commissioning is scheduled for the end of the year and is performed by Dr. Goessling.

The Dr. Goessling team was once again able to offer an individual design, meeting special demands and reaching full customer satisfaction. Dr. Goessling is looking forward to your application too and is happy to consult.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.