FOUNDRIES

#cooling, #sorting &

#batchloading

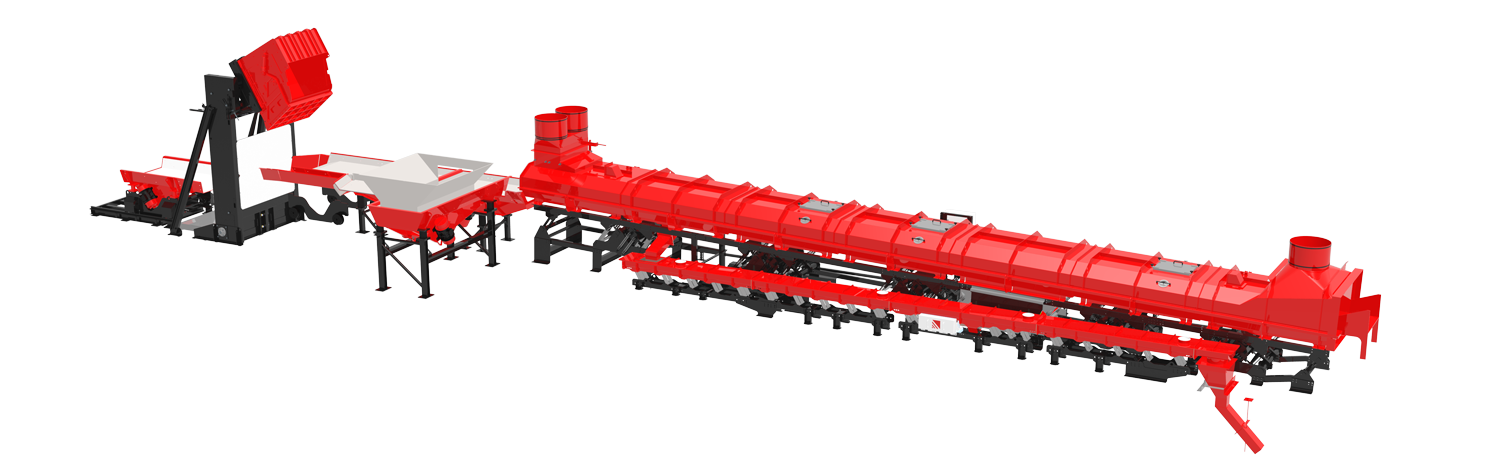

JOEST delivered several types of machines from its product portfolio for castings for a customer‘s complete system.

To simplify and enhance the original process of storing casting parts in boxes for the cooling process, a JOEST Casting Cooler was installed downstream the existing shakeout.

This eliminates the need for manual storage with a forklift, resulting in significant time savings. After passing through the casting cooler, the parts move to casting separation and sorting on a sorting conveyor before being transferred to a lifting and tipping device. Subsequently, a feeder on a drive frame feeds the parts to the shot blasting system in batches, ensuring a continuous material flow. In addition, a bypass discharge line is installed alongside.