FOUNDRIES

Customer of the Year

The Company ATIK has been working with JOEST machines successfully for years.

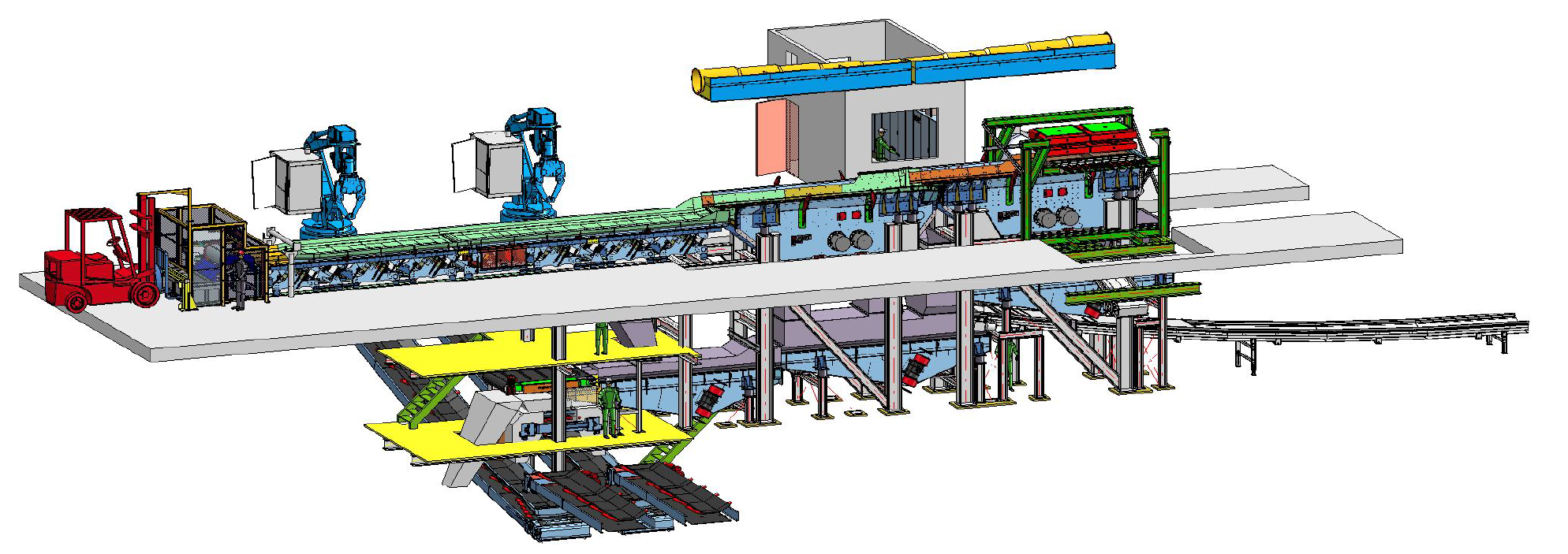

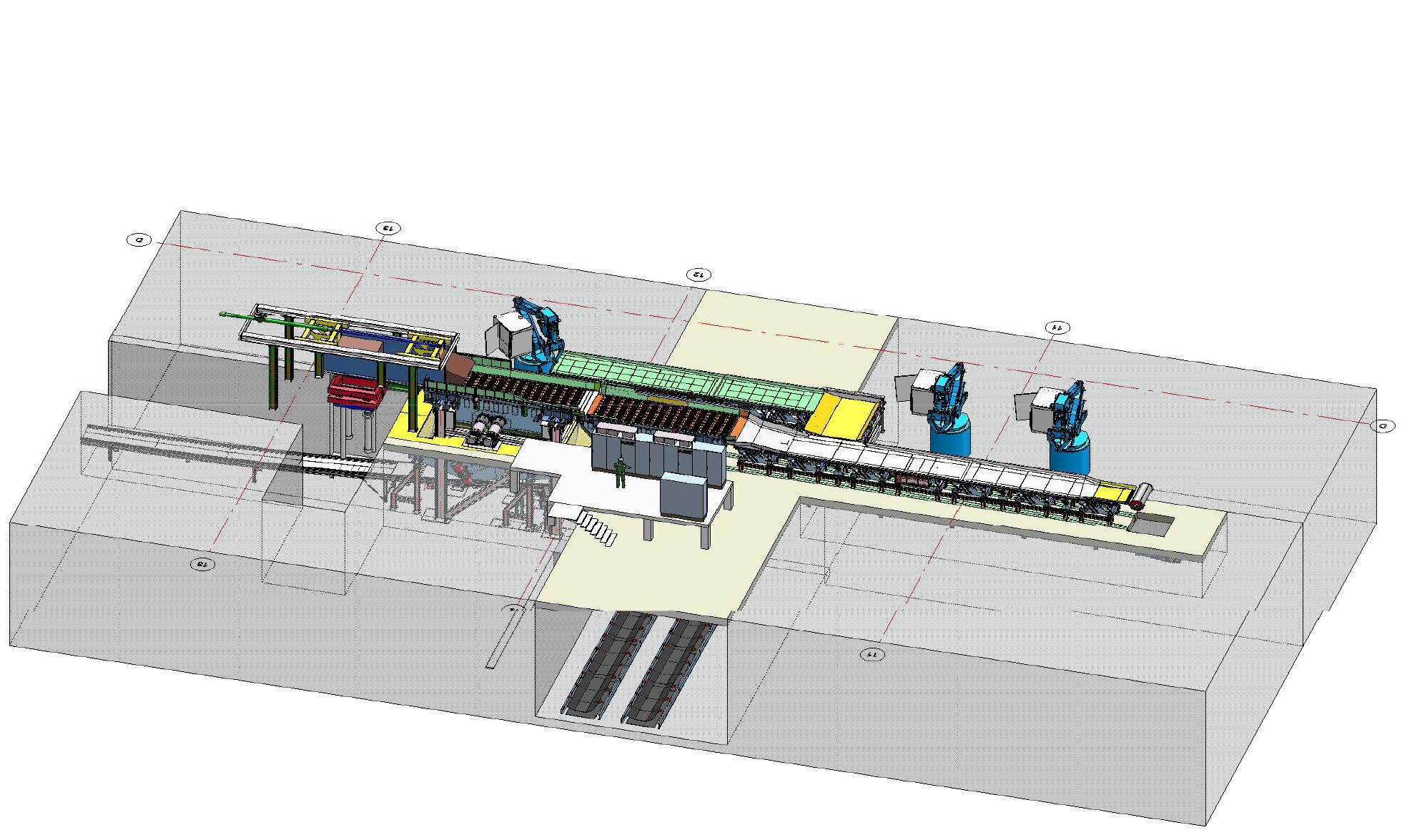

Atik Metal, one of the largest and most modern foundries in Turkey, producing mainly for export, makes a new investment. The Project includes two new HWS molding plants, the according Eirich sand processing with vacuum mixers and two custom shakeouts followed by manipulator supported cast processing technology.

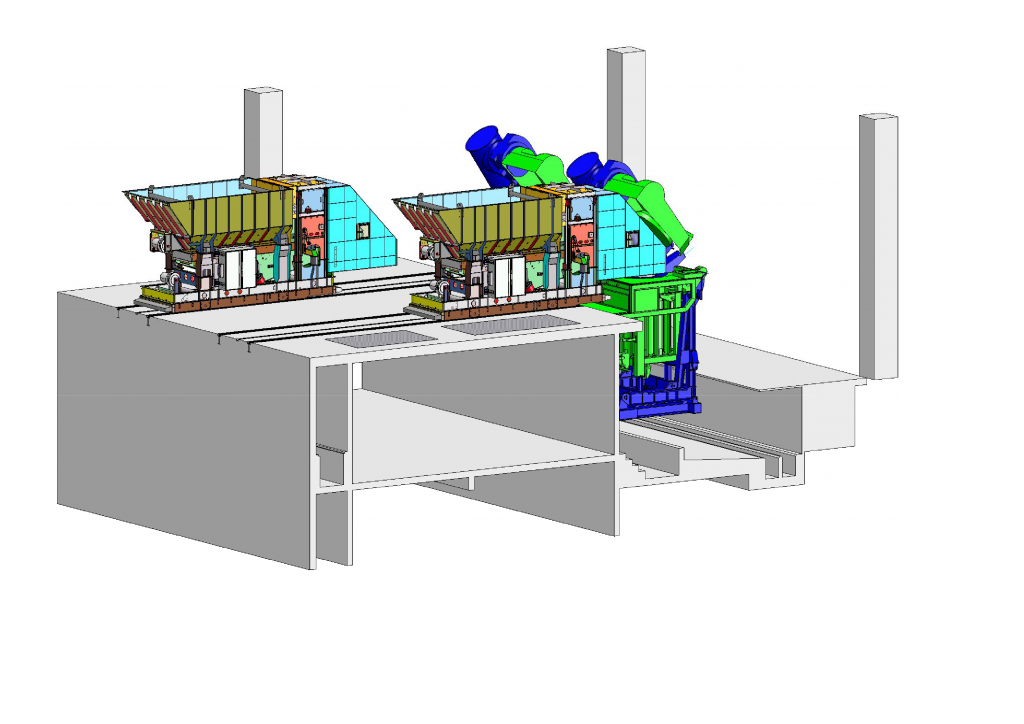

The implemented shakeouts are 2x2 shakeouts with electronically adjustable oscillation parameters. Sensitive casting parts that are not suited for shakeouts can be transferred to a parallel soft-handling line using the manipulators. This prevents Surface damages. On the following separating and sorting feeder, manipulators separate circulating material from the casts, which hen transferred to a hanging sand blasting plant.

All shakeouts are designed with a decline angle and weld-free side walls. Each casting conveyor is manipulator proof with solid, bolted spring beams. Additionally, JOEST is supplying six laterally displaceable charging vehicles with 12 tons of capacity each. They will feed the new induction furnaces.

JOEST is thankful for the many years of good cooperation and thanks Mr. Atik for the trust he places in JOEST. As a special thanks and sign of appreciation, Mr. Atik was awarded the title “Customer of the Year” in December.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.