STAMPING INDUSTRY

Disposing stamping scrap for the automative industry

One of the largest automotive suppliers relies on GOESSLING-Quality.

![]()

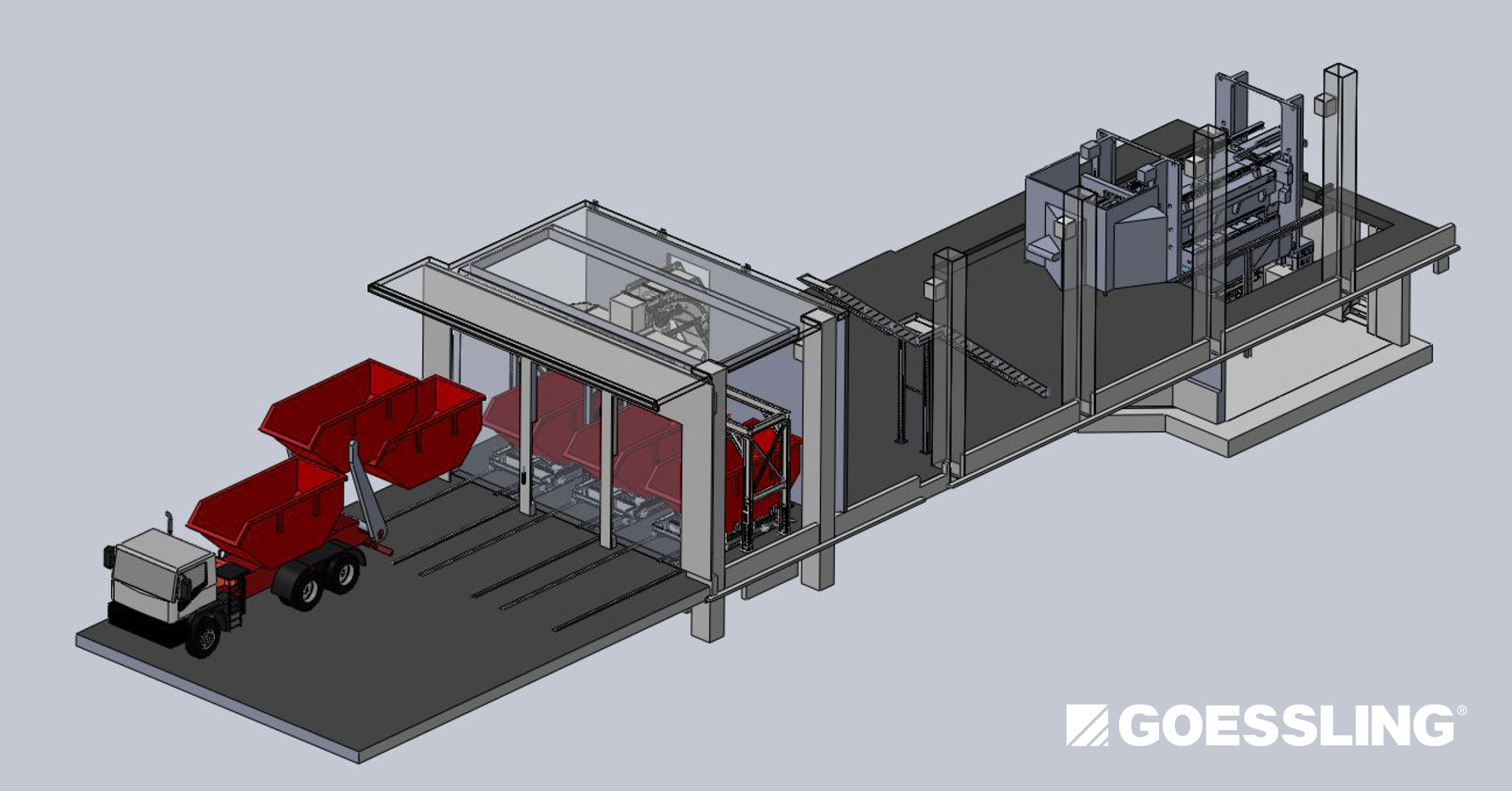

Once again, GOESSLING delivers its well proven conveying technology to Mexico for a client that already has multiple conveyors in operation around the world. For the disposal and separation of stamping scrap from manufacturing car bodies, the client relies on the quality and good experience with GOESSLING again.

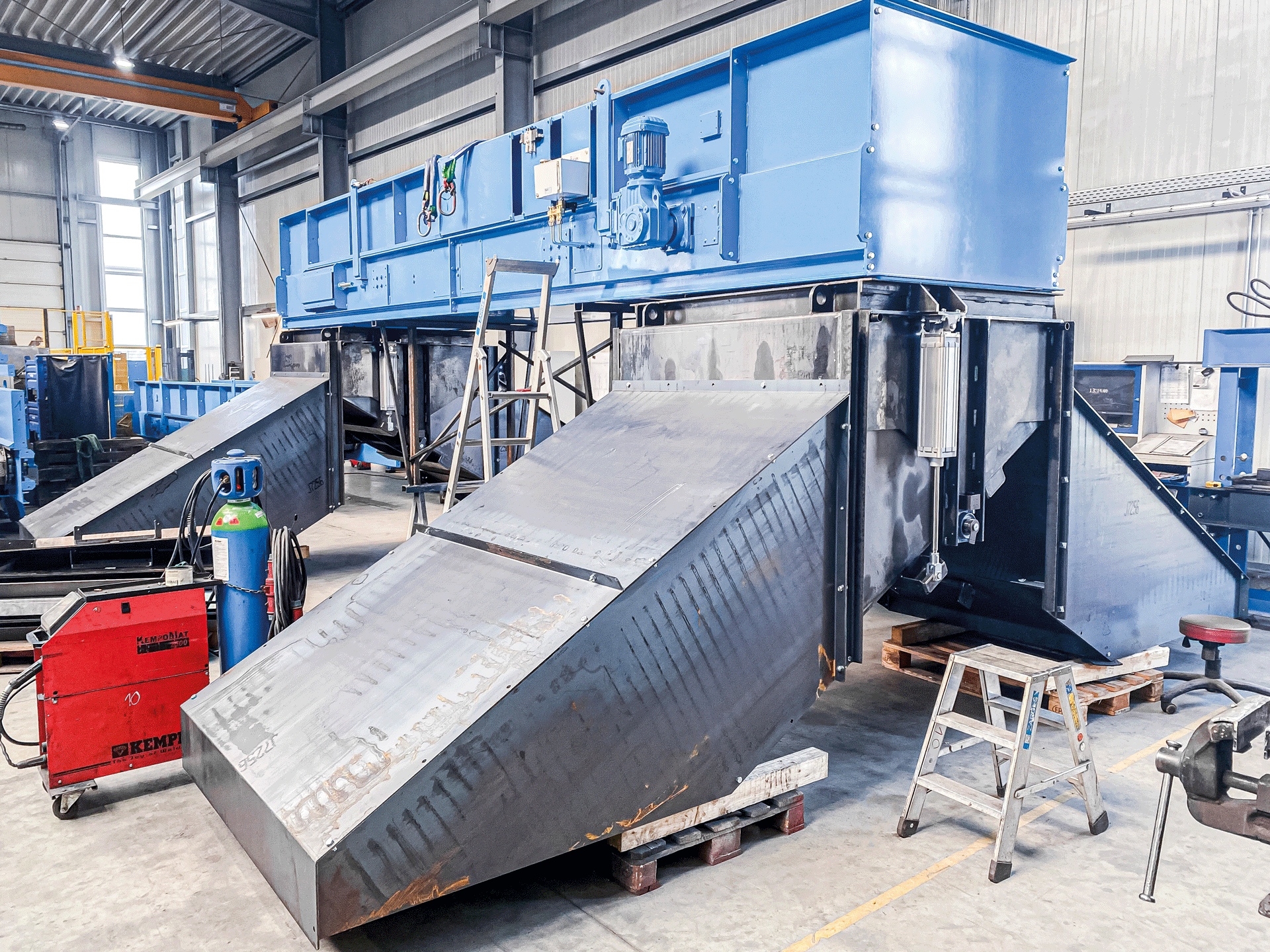

The objective here was to sort and dispose aluminum and steel scrap from a total of six steel presses. GOESSLING designed and manufactured eight Hinged Belt Conveyors with a combined length of 130 meters, a partition of 125 mm and an effective width of 1,025 mm. The sidewalls are specially designed for sheet metal scrap. The precision sidewalls of the steel hinged belt and the machined steel bar on the belt frame create a hermetical seal around the circulating curbs and drive chains of the conveyor. Additionally, the material is kept within the effective conveying width and material jams are prevented. The Hinged Belt Convey or is equipped with robust, low maintenance technology.

The conveyor started running in June, this year. During this project, GOESSLING was able to strengthen the good relationship to the client and is looking forward to exciting future projects.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.