METALLURGY

Inorganically core sand is separated and conveyed by JOEST-technology

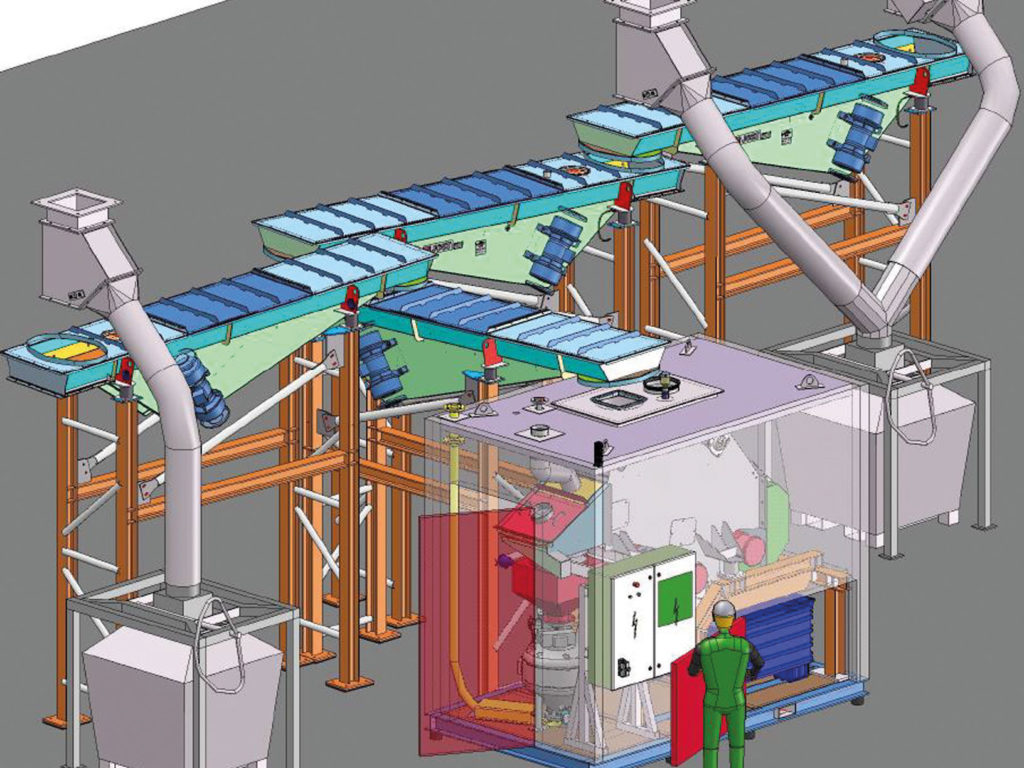

Reclaimed sand attrition units and sand transportation troughs for leading German automobile manufacturer

JOEST receives an order subdivided into multiple stages from a leading German automobile manufacturer, the first of which includes five modularly designed reclaimed sand attrition islands for inorganically bonded core sand from an aluminium foundry.

In order to manufacture complex cast iron parts for automobile engines and parts for electric cars from aluminium, a commonly applied process is the gravity die casting process. In the process, the outer contours of the cast iron part is manufactures in two parts as a permanent mould. The interior of the mould consists of chemically bonded core sand. When the cast iron part solidifies, the core sand residue is extracted using powerful mechanical oscillations.

The accumulated core sand is collected to so called “island points” using sand conveying troughs, which are located at multiple extraction points in the ceiling. The sand is then grinded be the reclaimed sand attrition units. The sand that is now broken down into single grains is now conveyed through a pipeline to a collection silo by pneumatic thrust conveyor using pressured air.

The delivery of the first stage contains five reclaimed sand attrition units in total and is scheduled for the end of 2019. JOEST says thank you for the trust and is looking forward to a successful implementation.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.