THERMAL PROCESSING

Plant for drying

cereal and high-protein resources

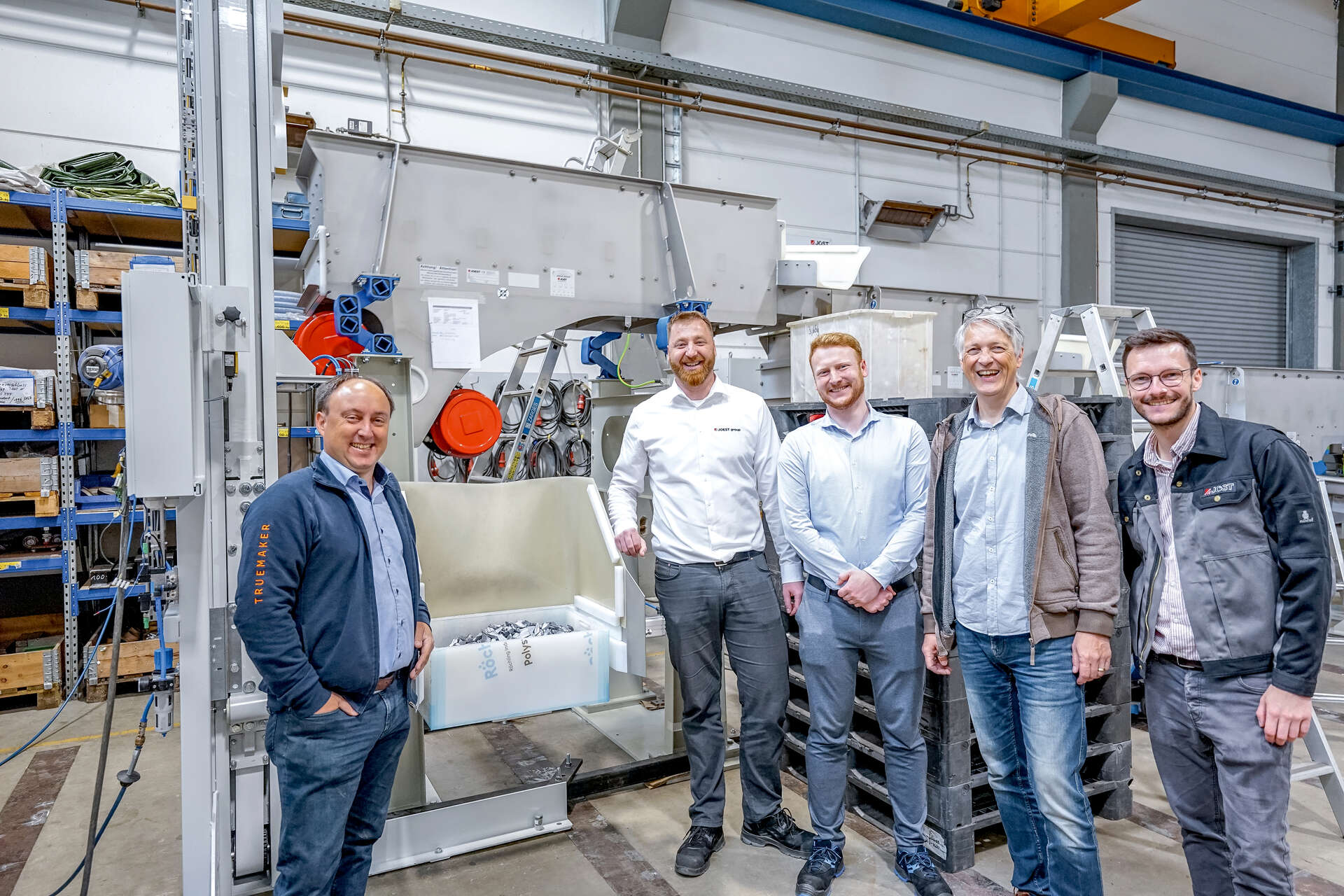

JOEST delivers drying system to Extruded Cereal Products B.V in Helmond.

After several vigorous meetings with the client from the Netherlands, JOEST was given the order to manufacture a large drying system. Extruded Cereal Products B.V. is a large producer of extruded cereal and protein products for the food- and animal feed industries.

The client was looking for a plant to dry wheat-based extrudates which vary in size and shape, composition, moisture and temperature. The existing factory offered very little room for the plant.

As a solution, JOEST delivered an extremely compact plant that was based on previous deliveries and optimizations in 2004 and 2014. The system covers four levels of the factory and uses a sophisticated pipeline layout to make the most of the available space.

Its main components are a JOEST Fluidized Bed Dryer, a downstream screen, the required processing technology, ventilation equipment and the electronic control featuring a process visualization. The ventilation equipment includes fans, a steam air heater, cyclones, pipelines and an exhaust air heat exchanger.

The Fluidized Bed Dryer is more than six meters long and features two drying and one cooling zone. The machine has an electronic oscillation-angle control which enables material retention times to be adjusted during full operation. This way the dryer can be set to optimally match each product. The settings can be saved in the recipe database of the individual product.

The air ventilation system incorporates a partial exhaust air recirculation. The preheated air from the cooling zone and the drying zone are reused for the drying process after being tempered. Additionally, the required fresh air is pre-heated by the warm exhaust air in a heat exchanger. This design results in an energy efficient operation whilst maintaining as much flexibility as possible for different product types. A screen following the dryer separates the material stream into three grain sizes. Furthermore, the entire equipment is noise and heat isolated.

Installation was performed by JOEST in October this year and the cold and warm start-up is scheduled for the end of 2021. Having started in 2004 with the old plant, the partnership and cooperation was expanded throughout this project. Everything worked out to the full satisfaction of the client.

The Fluidized Bed Dryer is more than six meters long and features two drying and one cooling zone. The machine has an electronic oscillation-angle control which enables material retention times to be adjusted during full operation. This way the dryer can be set to optimally match each product. The settings can be saved in the recipe database of the individual product.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.