JOEST AUSTRALIA

Right on time for

the anniversary, JOEST

Australia gets a new home

20 Years of successful company history.

First JOEST subsidiary looks back on a successful 20-year company history!

JOEST Australia was founded in January 2001, and since this time where JOEST operated from a leased office space in Kewdale, growth has seen that larger facilities were needed to build big machines for the mining industry sector.

It wasn’t long until in 2002, with some success in the mining sector in WA & NSW, JOEST decided to lease a larger factory area to enable the new subsidiary to assemble and test machines in house. A 500 m² workshop in Moriarty Road, Welshpool was leased.

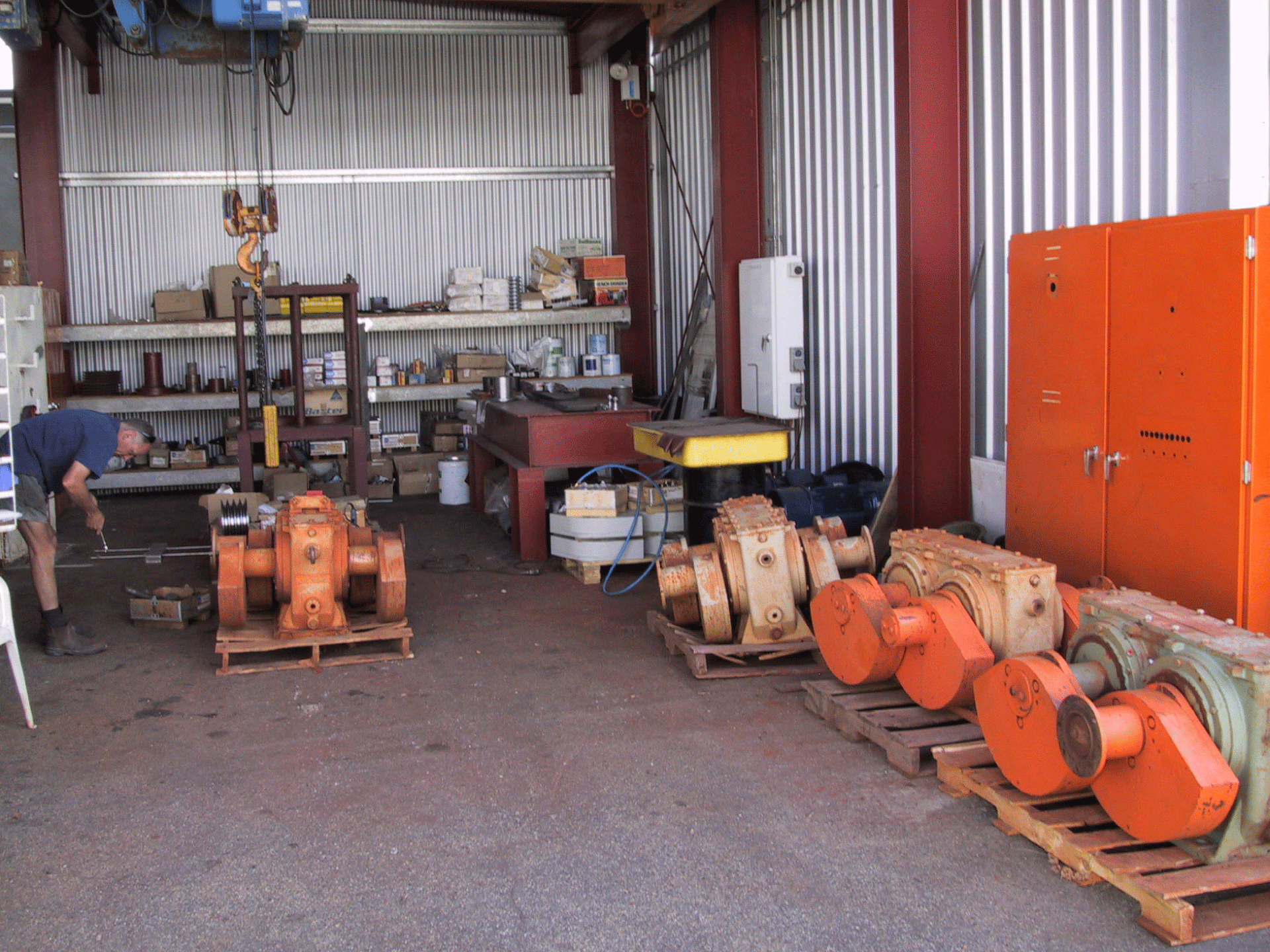

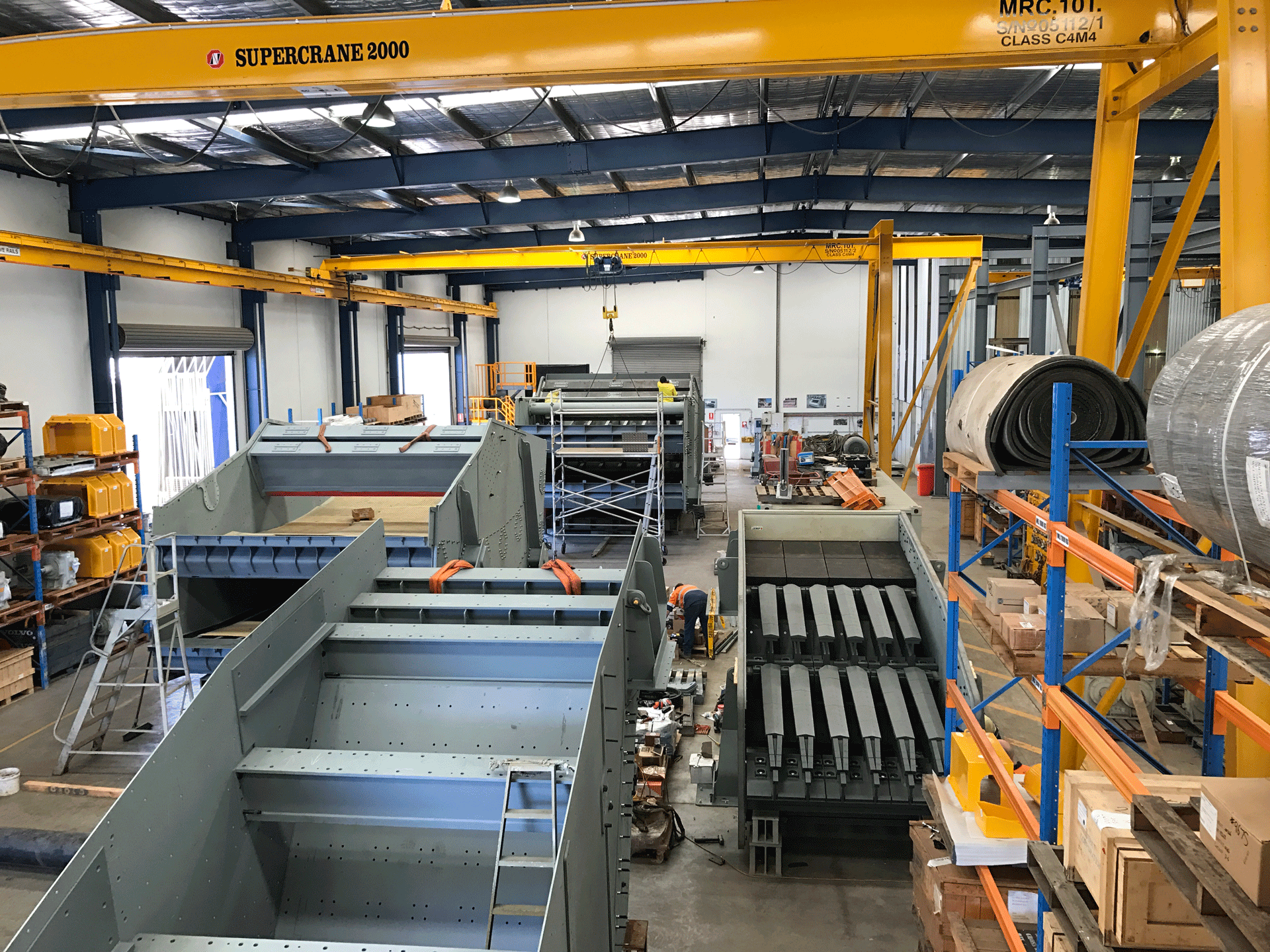

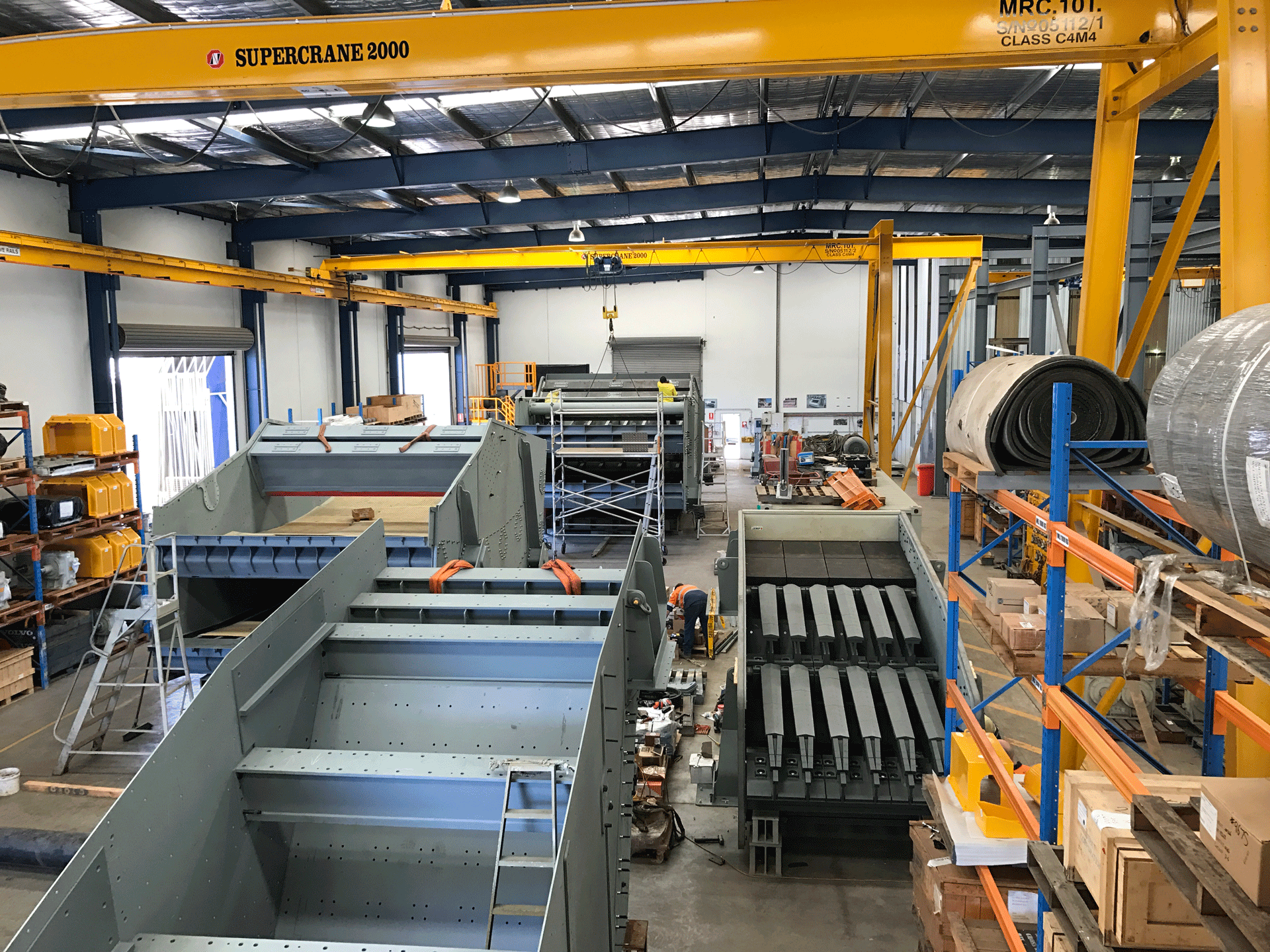

In 2006 JOEST moved to a new facility in Sheffield Road with approximately 1200 m² of factory space serviced by 2 x 10 tonne overhead cranes. Each relocation enabled JOEST Australia to take more orders and build a team to service the growing population of JOEST vibrating machines in the Australian market. In the following years with the increase in order volume, and size of the vibrating screens, it became clear JOEST Australia needed larger purpose-built facilities. Major projects with the tier one iron ore producers located in the Pilbara region of Western Australia fuelled the growth. High quality engineered products with a customer focused team brought more work to JOEST.

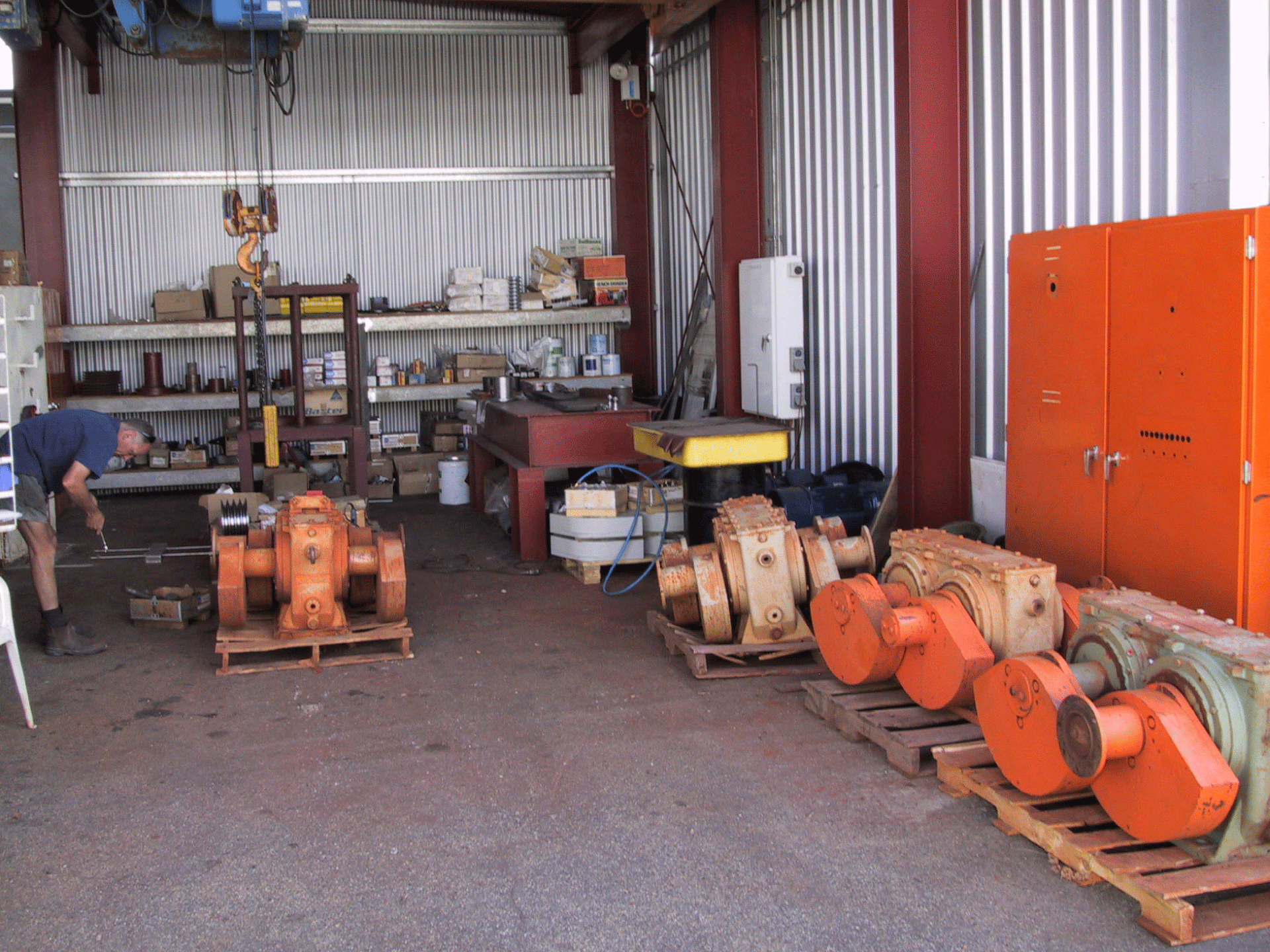

A side effect of the continuous success was an increasing lack of space to store parts and build machines. This led to inefficiencies and congested workspaces. Leasing additional space was a solution for the JOESTeam, however brought with it efficiency challenges and a segregation of the workforce, duplication of tooling and more.

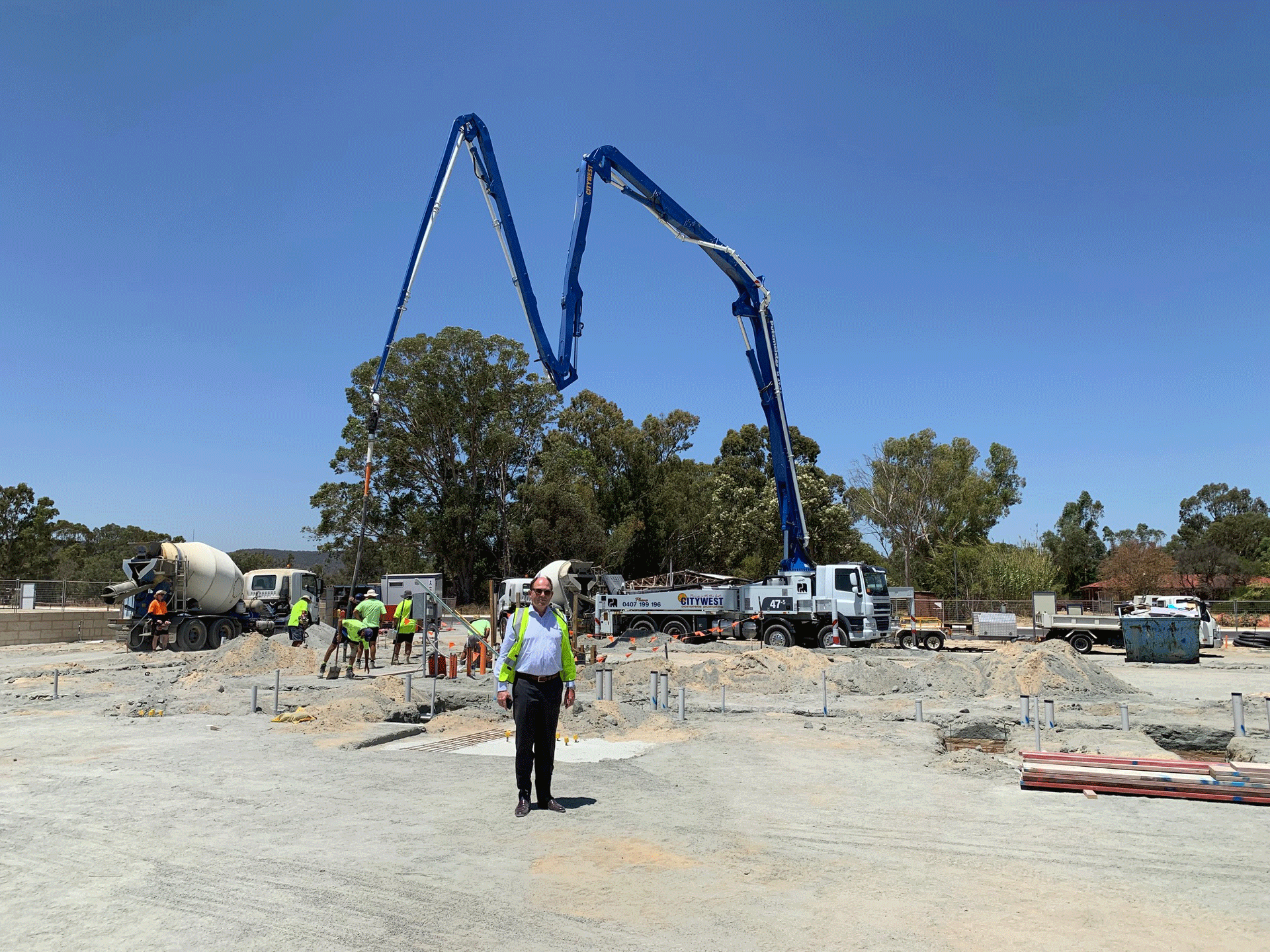

In order to solve these issues, Managing Director - Ian Laws engaged with architects Brooking Design Architects (BDA) in 2018. The goal was to define the key features needed in a bespoke facility to meet the current and future needs. Several potential land options were investigated, finally arriving at a new industrial estate “Row Highway Logistics Park“, a mere 1.5 km from the Sheffield Road headquarters. The 10,800 m² property offers plenty of room for the new, future-proof facility.

Proposals and budget project costs were presented to Dr. Moormann, Managing Partner of the JOEST group, in early 2019. With support and approval, the design phase began. Major design focus was on workshop spaces that enable an efficient and logical workflow. LEAN manufacturing techniques were to be a feature of the final layout.

As a result, three assembly bays now span 4000 m² of production surface. Two 50 tonne cranes and four additional 10 tonne cranes provide ample lifting power. The workshop features a special clean room including a 5 tonne crane for drive assemblies. There is also a large 10 m x 12 m surface treatment spraying booth with extraction fans as well as a specially designed vibration isolated test bed for Factory Acceptance Testing of large vibrating machines. Once a JOEST machine has been assembled and tested successfully, the new drive thru loading spacekaccess and departure. In addition to the well-thought-out workshop, office space with modern open plan workspaces provide great opportunity for communication. Also, well-designed meeting zones allow for team collaboration.

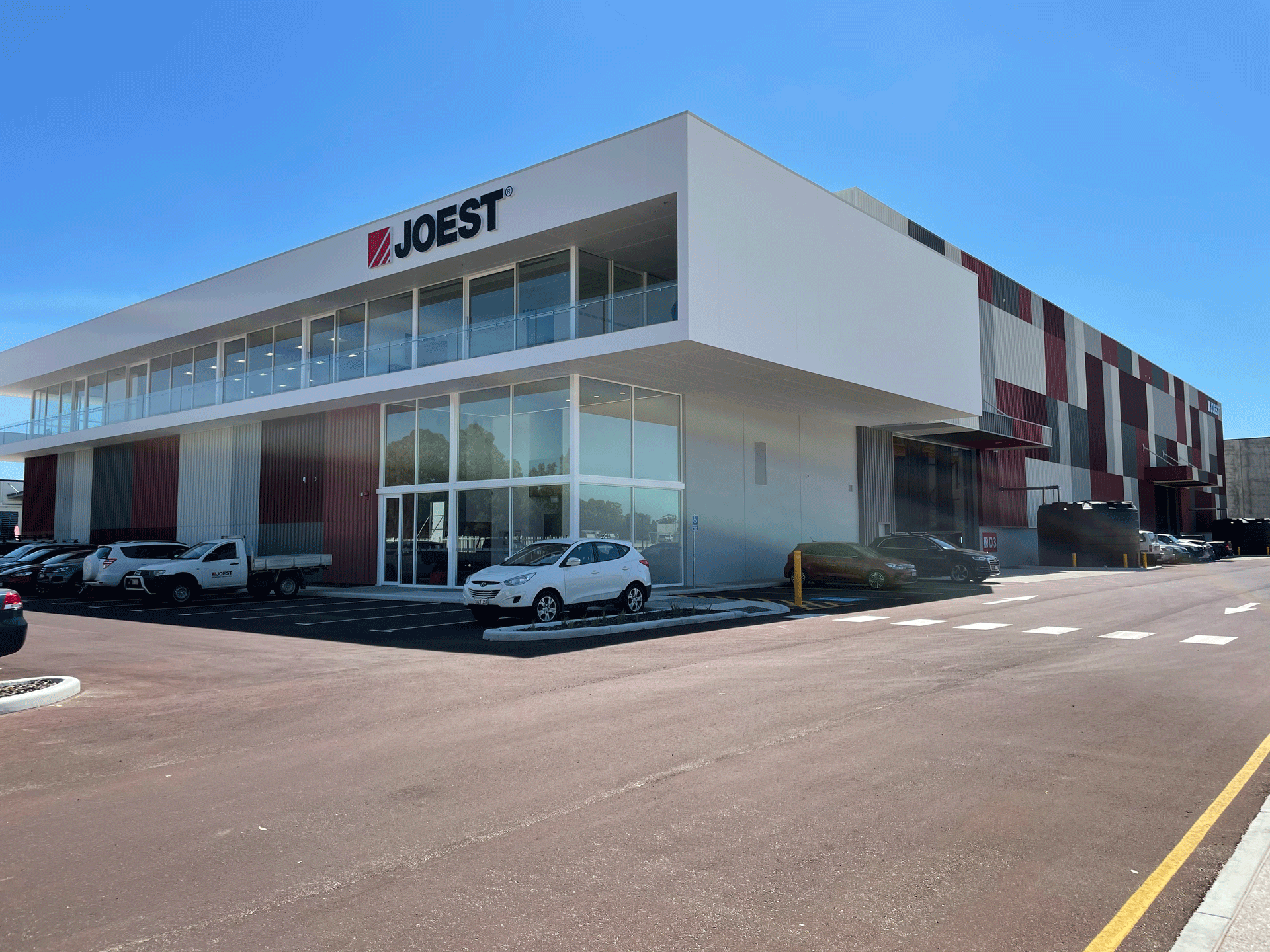

First team members relocated to Coldwell from the satellite ‘Bellows Road’ workshop, with the Sheffield team join-ing some two weeks later along with the office team. Since November 2020, JOEST Australia’s Perth based team members work ‘reunited’ at the new facility on Coldwell Road. The development is a step change to JOEST Australia’s ability to service Australian customers and provide innovative solutions. It provides the ability for JOEST to grow it’s footprint in the Australian market not only in machines for mining, but also in the growing recycling and processing sectors. The new facility also provides the JOESTeam members a modern, comfortable working environment, making JOEST a great place to work.

Today JOEST is considered amongst the world leaders in vibrating technologies, servicing the world’s largestmining companies, major contractors, as well as the local private operators. This latest expansion displays once again how the JOEST group is always thinking ahead and is prepared to provide its clients with an optimal service. Now, and in the future.

Australien

Das Video zum neuen Hauptsitz

We need your consent to use the YouTube service!

More Information

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.