LEBENSMITTEL

From Farm to Feed: MOGENSEN's

Compact Solution for Animal Feed Screening

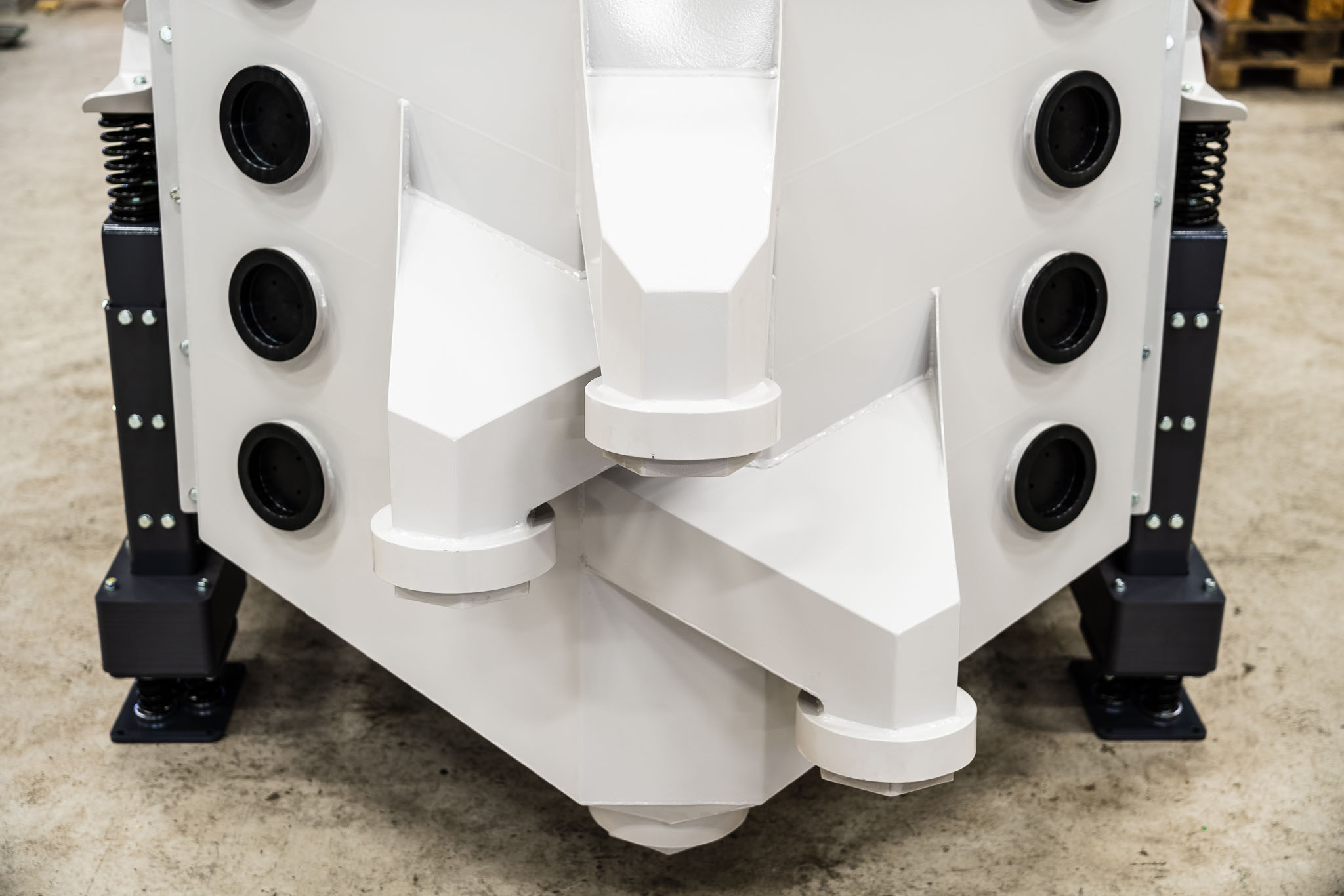

In the animal feed industry, space and time are incredibly valuable. As global demand for high-quality animal feed continues to rise, production efficiency becomes a top priority. MOGENSEN has established itself as a trusted partner to many leading feed manufacturers, with over 3,000 installations worldwide. A prime example of their commitment to innovation is the MSizer Compact – a powerful, space-saving machine designed for precise and fast screening processes. It is the ideal solution for screening raw materials and finished products with unmatched accuracy

Compact Performance for a Growing Market

The global animal feed market is experiencing record growth. Consumers are becoming more conscious of the quality and nutritional content of what their animals consume, driving the demand for precise, reliable feed production technologies. The MSizer Compact responds to these needs by offering a robust screening solution with a minimal footprint – taking up less space than a standard pallet – while delivering maximum output.

With the ability to process over 40 tons per hour of diverse feed materials, such as fishmeal, soybean meal, corn gluten meal, and various additives, this machine ensures efficient and clean screening for a range of animal categories. It achieves an impressive screening efficiency of 95% for feed pellets and granulates at separations of 14, 3, and 2 mm, thanks to its innovative vibratory screening mechanism, ensuring high precision.

Efficiency and Reliability in Feed Production

In an industry constantly pressured to innovate, the MSizer Compact stands out for its reliability and efficiency. Its ability to speed up production while saving valuable space helps manufacturers remain competitive in increasingly crowded markets, all while maintaining the highest quality standards.

Sustainability, Scalability, and Competitive Advantage

The MSizer Compact is more than just functional; it is part of a broader trend toward sustainable manufacturing practices. The MSizer Compact is more than just functional; it is part of a broader trend toward sustainable manufacturing practices.

As global regulations tighten and manufacturers aim to reduce their environmental footprint, MOGENSEN’s technology offers a solution that aligns with these priorities. The MSizer Compact contributes to reducing waste and lowering energy consumption. Its durability and low maintenance requirements also mean fewer resources are spent on repairs or downtime, allowing companies to focus on scaling their operations.

Industry 4.0 and the Future of Feed Production

The MSizer Compact is designed for the future, equipped with an electronic monitoring system that tracks key performance indicators like vibration, temperature, and throughput. This allows for predictive maintenance and process optimization, ensuring maximum uptime and efficiency. An automatic screen tension monitoring system detects any deviations that could impact performance, while an optional electrical heating system for the screen decks can be integrated with automated control systems to optimize screening based on material properties and environmental conditions.

Pioneering Solutions for the Future of Feed Production

From Asia to the America, MOGENSEN's screening solutions are transforming animal feed production. As global markets evolve and the demand for higher quality and sustainability increases, it’s not a question of if producers will adapt, but how quickly. While staying ahead of the curve is crucial today, redefining what precision, efficiency, and reliability can achieve is even more pressing. In a world increasingly driven by smarter solutions, the true challenge lies not just in meeting expectations, but in setting the standards of tomorrow.