FOOD

Successful collaboration for

innovative conveying technology

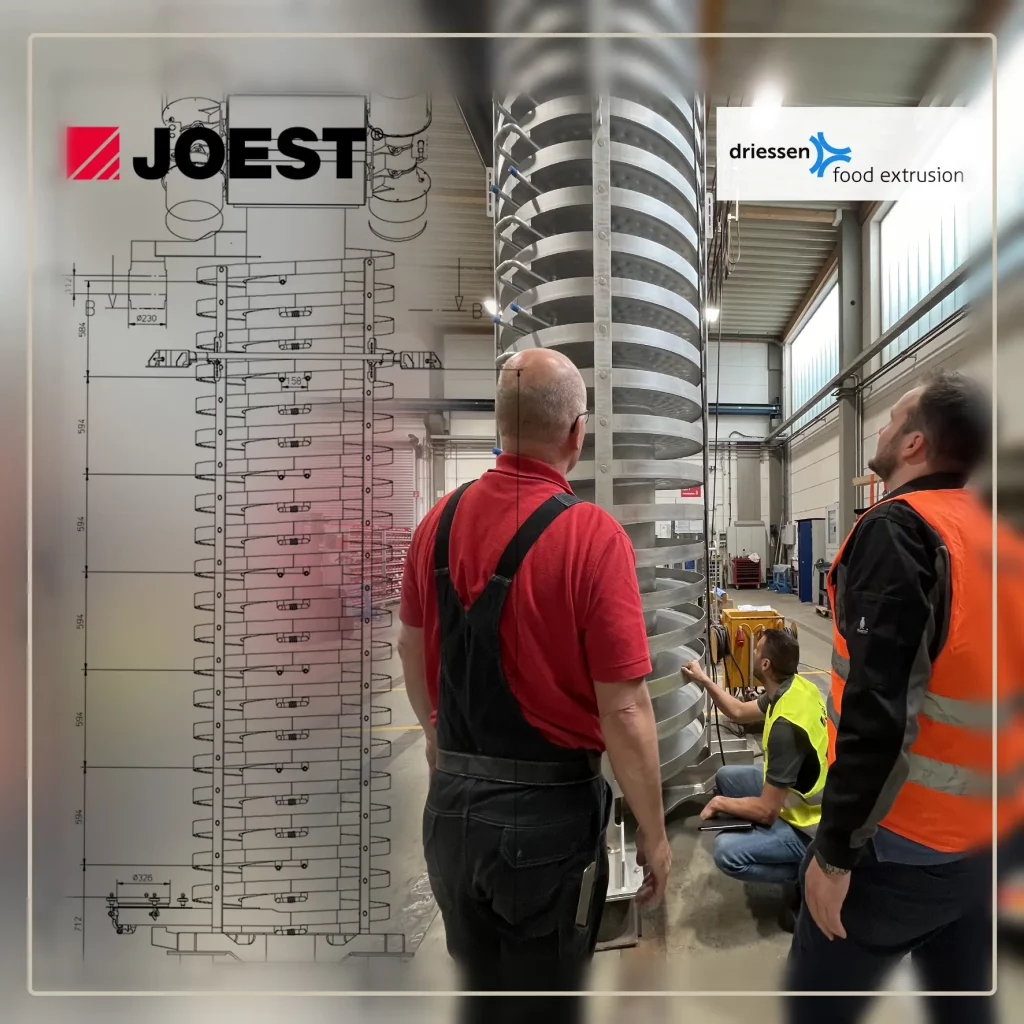

The long-standing partnership between JOEST and Driessen Food Extrusion has reached another milestone: the latest JOEST spiral elevator, specially developed for the vertical transport of freshly extruded, often sticky protein foods, was delivered to Deurne, the Netherlands, this week. The high-quality system ensures smooth conveying of challenging food products and thus meets Driessen's high quality standards.

Challenges in food processing mastered

Driessen Food Extrusion recently visited JOEST in Duelmen to carry out the final acceptance test of the spiral elevator. The spiral elevator - the second system JOEST has manufactured for Driessen - is used for the vertical transport of freshly extruded protein foods. These granules can be particularly sticky, which places high demands on the conveyor technology.

To meet these challenges, the spiral elevator is equipped with a double-walled system with oil heating, which prevents the products from sticking together and ensures a constant temperature during transportation. Thanks to this sophisticated design, the protein products are conveyed efficiently and gently.

Technical perfection meets customized solutions

JOEST conveyor technology is specially designed to meet the requirements of the food industry. With dimensions of 1950 mm wide and 3680 mm high, the system is both compact and powerful. The robust design and precise control system ensure even and reliable conveying, which is crucial for the further processing of foodstuffs.

The successful collaboration between JOEST and Driessen Food Extrusion illustrates the commitment of both companies to develop innovative and customized solutions for the food industry. Together, they are laying the foundations for a long-term partnership that will pave the way for future innovations.