JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

Conveying Technology

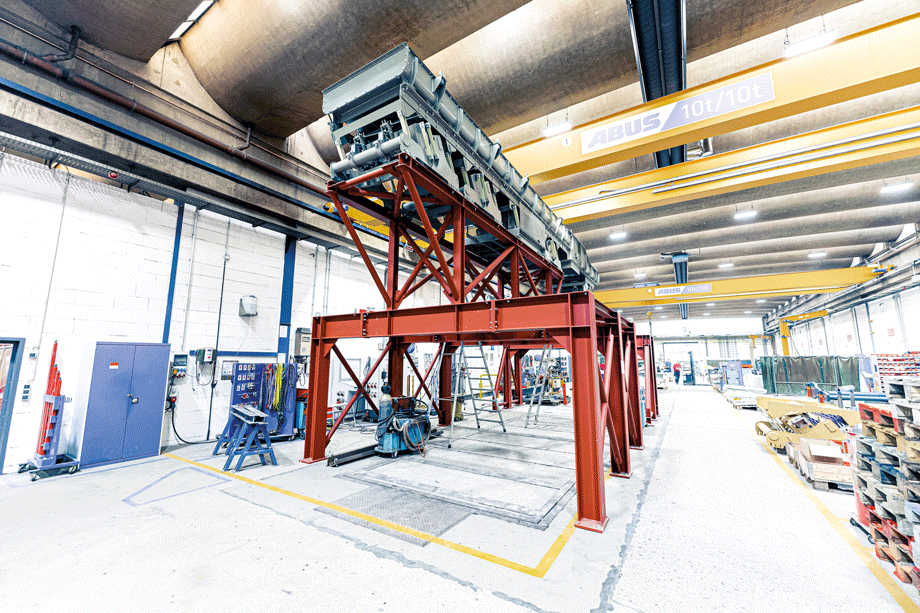

AEB replaces 8 Vibrating Conveyors

After more than 30 years, Amsterdam-based waste processing company AEB is replacing a total of eight JOEST conveyors to optimize slag transport and improve operational performance.

Modernization of the green sand molding line

At JOEST, we always focus on efficiency and reliability when it comes to successfully implementing complex projects. A current example of this is the full modernization of a green sand line at our long-standing partner Fritz Winter – and that in an impressively short time.

Vibrating Conveyor for Crystal Sugar

In February, JOEST secured an order for the delivery of a specialized 15-meter-long vibrating conveyor for a Serbian producer of sugar products. This machine is an integral part of the production process, conveying freshly centrifuged sugar with a throughput of up to 70 tons per hour at a moisture content of 0,2-0,4% and a product temperature of about 65°C.

Innovative Foundry

Technology

At JOEST, we take pride in optimizing our customers’ production with innovative technologies and customized solutions. A recent example is our collaboration with HYDROTEC Technologies AG, an internationally operating company with over 50 years of experience and a clear vision: to continuously improve.

Innovation in recycling: OSCILLA FlexFeed

This innovative conveying solution with dimensions of 1950 mm wide and 2640 mm long sets new standards in the processing of moist and fine-grained waste slag. For a rust-ash processing system from Eggersmann Anlagenbau, JOEST installed a modern OSCILLA FlexFeed flip flow feeder.

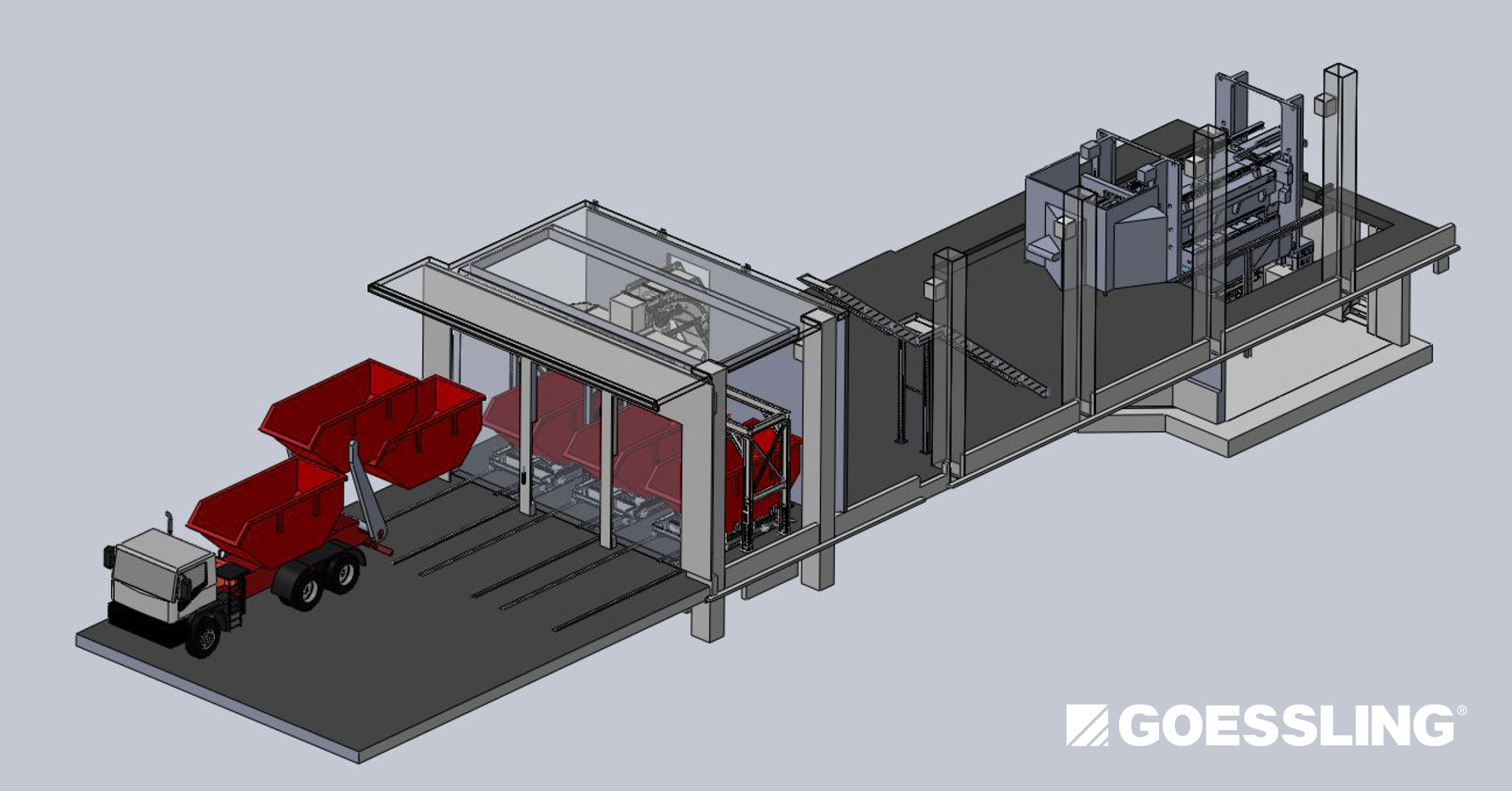

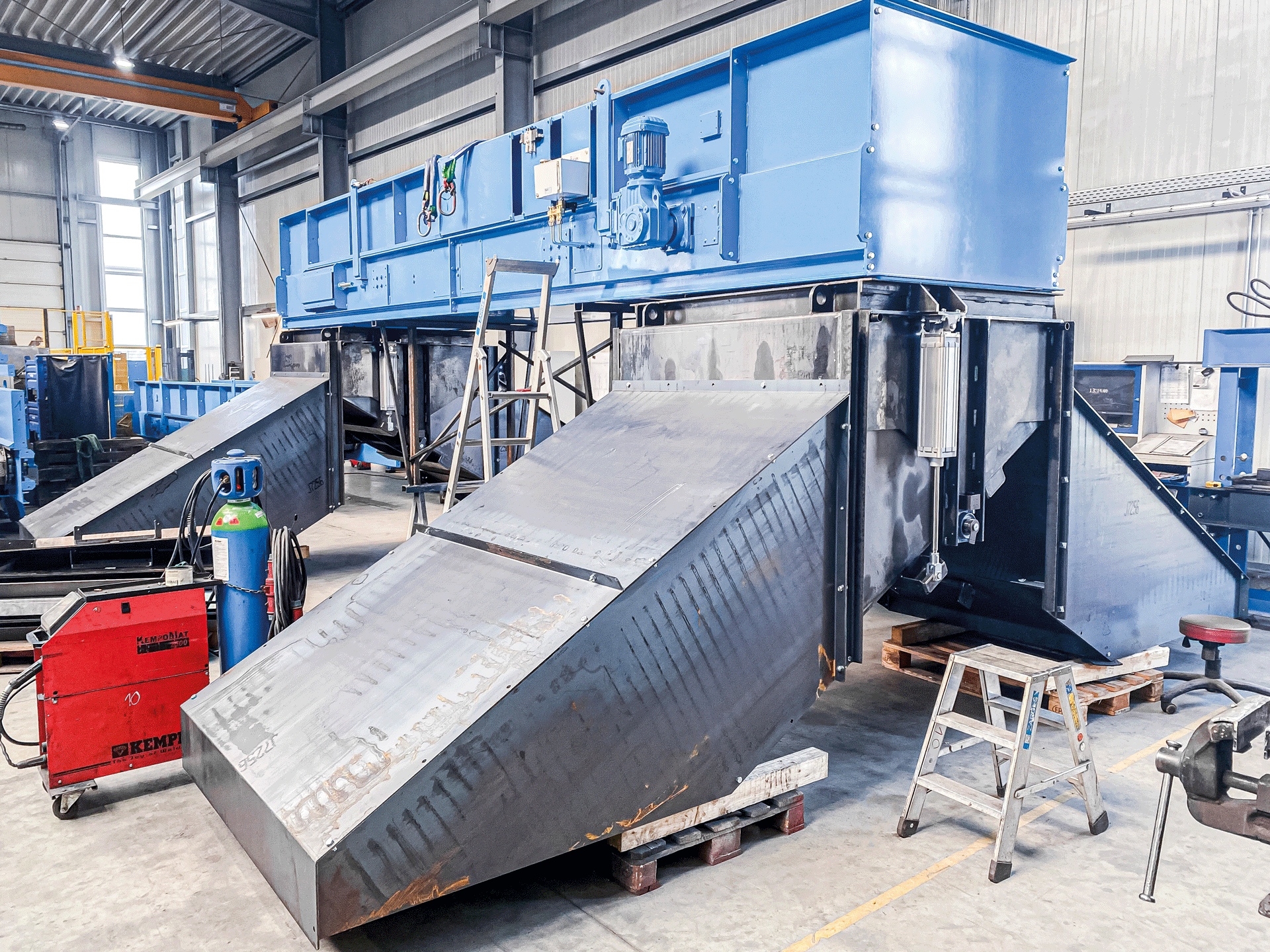

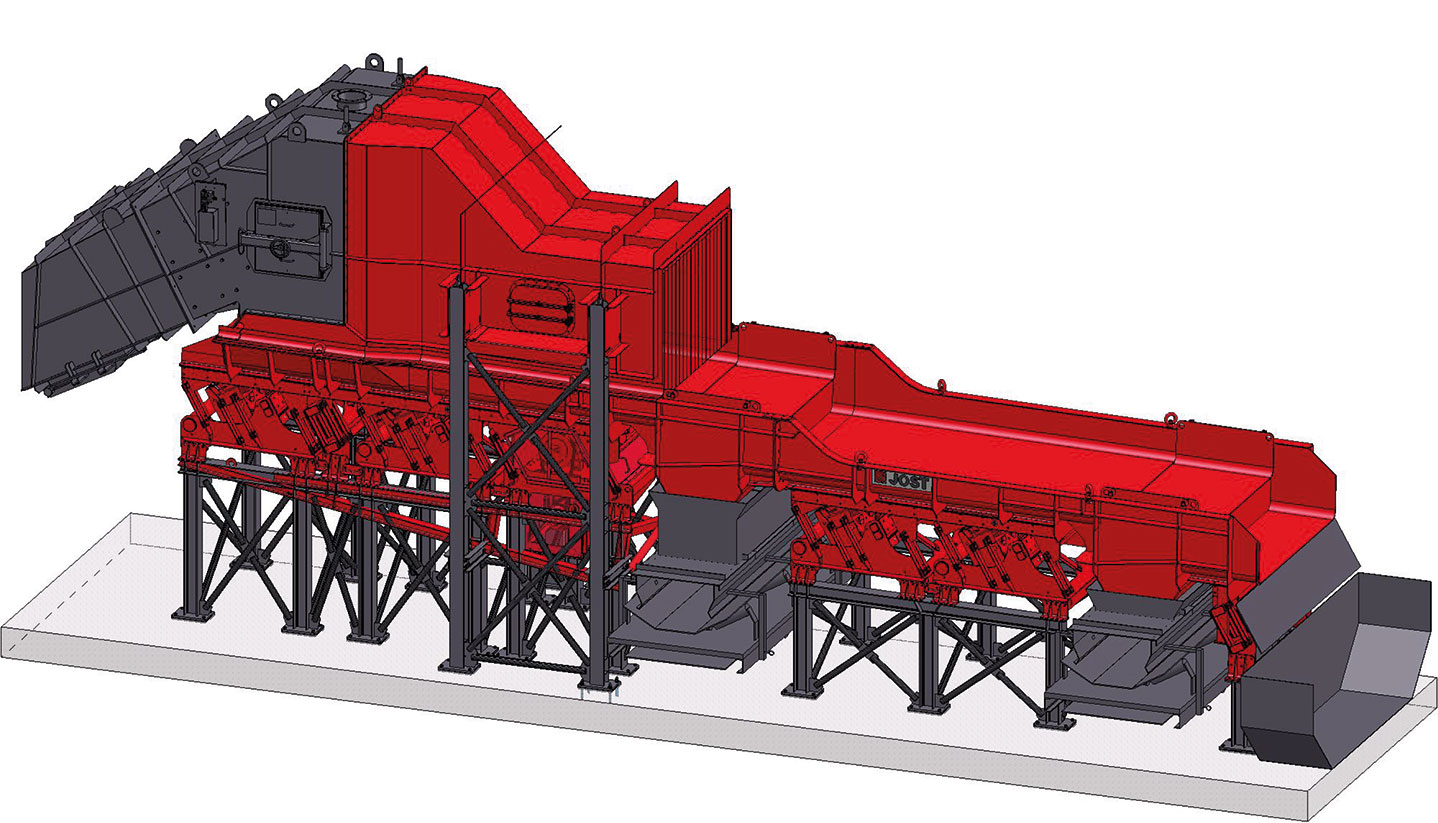

#EcoMelting: Charging vehicles for more sustainability

Exciting project for sustainability: the largest machines we’ve built to date – two massive 30-ton Charging Feeder. These machines play a critical role in reducing CO₂ emissions on a large scale.

Successful Project Completion

JOEST delivered two high-performance vibrating feeder including tunnel frame, discharge chute and needle gate, each one feeding gabbro up to an edge length of 700 mm as a free stockpile discharge. Our focus was on a robust, blockage-free, wear-optimized and installation-friendly design.

Half Time reached!

For our long-standing customer, Dyckerhoff company, we have now exchanged JOEST tube type feeder at two star distributors for silo loading during the winter overhaul for the 4th year in a row, thus reaching the halfway point of the overall project.

#cooling, #sorting & #batchloading

JOEST delivered several types of machines from its product portfolio for castings for a customer‘s complete system. To simplify and enhance the original process of storing casting parts in boxes for the cooling process, a JOEST Casting Cooler was installed downstream the existing shakeout.

Resonance Conveyor for Slag

The high requirements of waste to energy plants as well as systems with low energy demands are no novelty for JOEST.

With these resonance conveyors for Hitachi Zosen Inova, the material can optionally be fed to another unit via an intermediate opening with integrated JOEST Grizzly Screen. Another highlight is the low drive power of only 4 kW.

Quiet and gentle conveying technology

GOESSLING has worked with their client KAMAX in Hessen even prior to the acquisition by JOEST group. The KAMAX group is a leading supplier for heavy duty fasteners for the transportation industry and others. Through several projects in the past, a strong cooperation has been built. Once more, the division GOESSLING was able to convince with the right machines and its expertise and received another order. The client’s demand was to handle the discharge of screws from a thread roller into the client’s containers in a quiet and gentle fashion. An automated operation and complying to space restrictions on site were additional demands.

As a solution, GOESSLING designed and manufactured an L-shaped Hinged-Belt Conveyor with an adjustable incline. The machine has an effective width of 400 mm and an axle-base of 2.400 mm with an incline of 35 degrees.

Four-way travelling JOEST Charging Vehicle

For the optimization of the foundry and to improve the production process, the Bosch Rexroth AG in “Lohr am Main” is adding a third furnace to its automatic charging system which currently features two furnaces. For this project, a new furnace platform is being built in the neighboring building. The task for JOEST was to find a solution, so that the existing feed equipment for the furnace Charging Vehicles could be reused. The vehicles are fed with metal scraps and additive materials needed for the melting process, both of which are bound to their original location.

Scrap disposal with three movable containers

This year in September, the division GOESSLING delivered a customized conveying solution to a long-term client that once again relied on the high quality and positive user experience. When manufacturing chassis parts, stamping scrap occurs beneath the stamping press. These scrap parts must be disposed in containers. Using their experience in GOESSLING conveying technology, JOEST was able to offer the client a robust solution with excellent service. The special challenge of this project was that the stamping scrap is charged over a special chute system in the basement onto a Double-Z-Conveyor with an effective width of 625 mm. The scrap is then transferred on a reversible conveyor with the same effective width. At the the transitions, the reversible conveyor has pivoting chutes. The both pivoting slides enable the oily scraps to be distributed into three displaceable containers.

Drying system for extruded proteins

The food manufacturer Driessen Food Extrusion located in Deurne, Netherlands processes mixed, powdered, plant-based proteins to high quality ingredients for the food industry. In order to modernize their production and increase productivity, Driessen Food Extrusion is planning to build a new production line. JOEST received a contract last month to provide large parts of this new production line. For the processing of extruded proteins and production high quality coatings, the #JOESTeam will design and manufacture a complete drying plant. The planned drying system consists of a Fluidized Bed Dryer with processing-, heating-, cooling- and used-air systems as well as a Spiral Conveyor. The system will be delivered in spring 2023.

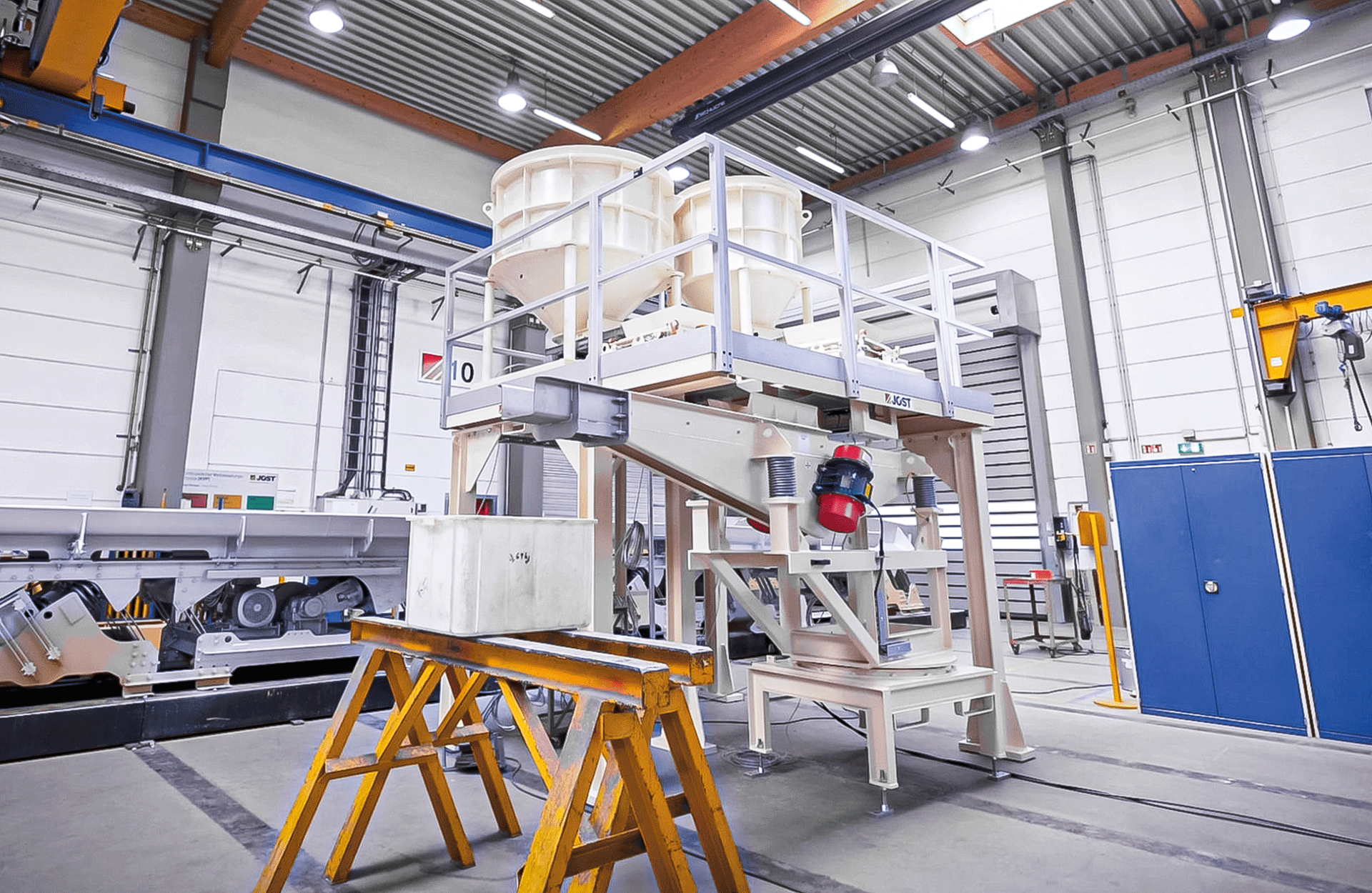

Alloy Plant for pan dosing

In June this year, JOEST delivered a customized solution for casted pan dosing to a German client. This specially designed alloy plant features a remarkable dosing precision for aggregates. The client’s demand was to achieve the best precision possible when dosing the two components manganese-iron and silicon-iron. The two hoppers are loaded with the aggregates by the client. Dosing feeders then feed the two container wagons. The wagons are pre-dosed to roughly 20 kg to speed up the actual dosing process. The downstream feeder, which can pivot by 90°, then feeds the material directly into the pouring stream. Depending on the aggregate, the system is designed to dose between 5 and 10 kg and each scale reaches a precision of up to 50 grams.

Disposing stamping scrap for the automotive industry

Once again, GOESSLING delivers its well proven conveying technology to Mexico for a client that already has multiple conveyors in operation around the world. For the disposal and separation of stamping scrap from manufacturing car bodies, the client relies on the quality and good experience with GOESSLING again. The objective here was to sort and dispose aluminum and steel scrap from a total of six steel presses. GOESSLING designed and manufactured eight Hinged Belt Conveyors with a combined length of 130 meters, a partition of 125 mm and an effective width of 1,025 mm. The sidewalls are specially designed for sheet metal scrap. The precision sidewalls of the steel hinged belt and the machined steel bar on the belt frame create a hermetical seal around the circulating curbs and drive chains of the conveyor. Additionally, the material is kept within the effective conveying width and material jams are prevented. The Hinged Belt Convey or is equipped with robust, low maintenance technology.

Automatic feed systems for welding studs and flange nuts

JOEST manufactured two automaticfeed systems to convey, sort and feedwelding studs and flange nuts. Thesystems are built up of an overheadconveyor with a link chain, a storage container, a linear feeder and a workpiece recirculation. The workpieces are provided manually in a storage container with an effective volume of 320 liters. The container has a steel design and is lined with PU plates. It also features a filling level indicator. The parts are presorted by workpiece specific carrier rails, conveyed upwards and fed into a linear feeder. The linear feeder is equipped with two parallel sorting feeders. On these feed-ers, alignment mechanisms force the workpieces into the correct orientation. Excess or falsely orientated parts are rejected by the linear feeder and are recirculated to the storage container. The sorting feeders are equipped with pneumatic deflectors to prevent the magazine from overflowing and to control the feeding lane in case a screw is left out.

A global player from Westphalia

Mit einem frischen und komplett neuen Design, inhaltlicher Überarbeitung

und einer übersichtlicheren Struktur erfahren Sie alles über uns und unsere Lösungen in der Förder- und Verfahrenstechnik.

Standard products combined with custom built machines

For a client building a phosphatizing plant as a general contractor for a German automotive company, JOEST designed, manufactured and delivered a large system solution this year, to feed and refill the plant. The project started in 2019 but was temporarily set on hold due to the Covid-Pandemic. It was later picked up again and went into production this year. The task was to dose forging parts into baskets provided by the client, based on the demanded formula. The parts are supplied in two different steel containers. The filled baskets are fed into the phosphatizing bath. After the phosphatizing process, the containers are removed and emptied.

JOEST Shakeout with electronically adjustable oscillation parameters

For a client from the foundry industry based in Croatia, JOEST designed and manufactured a Shakeout. Its frequency and oscillation angle can be adjusted electronically, and this design includes a downstream feeder with dual-lane discharge. The machines were delivered to Croatia during the second fiscal quarter of 2021. Commissioning is performed and overseen by JOEST and is planned for this summer. The client ‘s demand was to provide a reliable Shakeout that could handle a large spectrum of parts whilst maintaining a small form factor due to space limitations on site. The machine should separate as much sand as possible without damaging the casts made of GERMANY. Cast-/Sand-Shakeout after green sand forming line. JOEST Shakeout with electronically adjustable oscillation parameters gray cast iron and spheroidal graphite iron.

63 meter Hinged Belt Conveyor for stamping scrap

To replace the existing main conveyor in the client’s plant, Dr. Gössling Maschinenfabrik once again manufactured a conveyor to transport scrap from metal plates for the automobile industry…

100 m Conveying Cooler for forging party

Dr. Goessling Maschinenfabrik GmbH delivered a conveying system specifically optimized for the client…

Conveyor plant for quality inspection of aluminum forging parts

For a longstanding client with expertise in metal processing, Dr. Goessling Maschinenfabrik GmbH designed a special conveyor plant…

Fully automated de-oiling, washing, cleaning and drying of screws – within a single system

Maximal throughput when de-oiling and cleaning screws or small parts of various dimensions…

Process engineering solutions in glass recycling

Recycling is a growing market – especially in glass recycling new plants are currently arising or existing ones are updated and upgraded…

JOEST displays at VRAC TECH in Le Mans, France

From 1.-3. October, one of JOEST Manutation Par Vibration’s main attractions was a circuit consisting of JOEST and DIETERLE® machines…

Blumenbecker and JOEST working together successfully

Blumenbecker Automatisierungstechnik develops control system for a JOEST project in a metal foundry in Mexico…

JOEST convinces with absolute cleanness

For the second time, JOEST built a highly pure tube-type feeder for plastic pellets, which are used as base material in the production of electric cables. The challenge in building such a machine is the extremely high demand towards the surface quality and overall cleanness of all of the components. Foreign particles could lead to imperfections in the cables.

JOEST displays on POWTECH again

For the first time, the in-house brand DIETERLE® reinforces the trade show stand. Exiting exhibits attracted many visitors to the 72 m² JOEST stand at the POWTECH 2019…

With strong support from the in-house brand DIETERLE®, JOEST is once again present at POWTECH this year!

To kick off the trade fair year 2019, JÖST GmbH + Co. KG will once again exhibit at the most important trade fair for powder and bulk, granulate, chemical and thermal processing technologies…

HEXION excited from JOEST quality

Great teamwork – satisfied customer. Hexion GmbH, one of the world’s leading specialty chemicals companies, ordered a JOEST cooling conveyor to cool duroplastic molding compound…

Hot, hotter, JOEST!

JOEST supplies a spiral elevator for active carbon with a feed temperature of up to 300° C. In June 2018, JOEST sold an approximately 7 meter high spiral conveyor to a customer in the Netherlands…

High performance vibrating trough from JOEST for bottom ash at waste energy company AVR.

JOEST, specialist in vibration technology, optimizes the transport of bottom ash at the waste energy company AVR in Rozenburg, Netherlands…

Large Brazilian sugar company expanding processing line

JOESTMavi important manufacturer for sugar industry…

Unique feature makes JOEST the favourite in waste incineration

At the end of 2017, JOEST will supply four resonance conveyors to Hitachi for a waste-to-energy plant…

Major success thanks to JOEST technology

JOEST is the only manufacturer in the world that builds mass-compensated resonance conveyors (FSM) for the transport and coarse separation of incinerator ash…

Smart foundry in Turkey equipped with JOEST machines

JOEST delivered the complete vibrating machines to Trakya Dokum’s new smart foundry in Turkey…

Handling of iron ore in a small space

In the middle of June 2017 JOEST delivered two hopper discharge feeder with very high process engineering and installation requirements…

BPS/JOEST ASR processing plants for the USA

BPS – Best Process Solutions, Inc. and their German partner JOEST are supplying a complete processing system in the USA for the recovery of fine metal with a grain size smaller than 12 mm…

JOEST excels in car recycling with the Flip-Flow Screen TOPCILLA

For a world-leading US processor of car recycling, JOEST has produced one of its biggest TOPCILLA flip-flow screens yet for classifying light materials…

Heating Up International Cooperation

JOEST US was approached by one of the world’s leading scrap aluminum companies to provide ideas…

Product conveyance distance about 47 meters? JOEST has the solution!

47 meter-transport of waste slag with JOEST Vibrating Trough Type Feeder FSM…

Castings and Sand Transport with the JOEST Vibrating Through Type Feeder

Type FSM as a heavy version with vibration width regulator…

Major order for a bunker discharge system with two screening machines

OEST received an order for a bunker discharge system with two screening machines for a German steel plant. The screening material is coke…