Recycling is a growing market – especially in glass recycling new plants are currently arising or existing ones are updated and upgraded…

Drive Technology

JOEST delivers special vibration table for german stainless-steel producer

For this assignment, JOEST designed a compaction table measuring 1800 x 1800, with a deck load of 12 t and an adjustable oscillation frequency of up to 33 Hz…

JOEST presented its newest innovations at the GIFA 2019!

As a team with the in-house brand DIETERLE®, JÖST GmbH + Co. KG once again presented its products at the GIFA…

JOEST convinces with absolute cleanness

For the second time, JOEST built a highly pure tube-type feeder for plastic pellets, which are used as base material in the production of electric cables. The challenge in building such a machine is the extremely high demand towards the surface quality and overall cleanness of all of the components. Foreign particles could lead to imperfections in the cables.

High performance vibrating trough from JOEST for bottom ash at waste energy company AVR.

JOEST, specialist in vibration technology, optimizes the transport of bottom ash at the waste energy company AVR in Rozenburg, Netherlands…

Furnace loader for car batteries recycling system

JOESTMavi convinced by experience…

JOEST US – Your partner for foundry industry

JOEST US Adapts to Bell Foundry’s Shake Out Needs…

Unique feature makes JOEST the favourite in waste incineration

At the end of 2017, JOEST will supply four resonance conveyors to Hitachi for a waste-to-energy plant…

Advantages of the JOEST Double-Shaft Screen

Linear and elliptical motion combined in one screen…

Smart foundry in Turkey equipped with JOEST machines

JOEST delivered the complete vibrating machines to Trakya Dokum’s new smart foundry in Turkey…

Delicious fruit gum thanks to JOEST dosing feeder

JOEST Dosing feeders are compact and powerful magnet vibration conveyors which are equipped with the proven JD Dosing Drive…

Handling of iron ore in a small space

In the middle of June 2017 JOEST delivered two hopper discharge feeder with very high process engineering and installation requirements…

The right combination – the K-Sifter in combination with the Air Separation Table

JOEST has been supplying vibration technology for ninety-five years – and that means ninety-five years of experience in the design and production of vibratory machines…

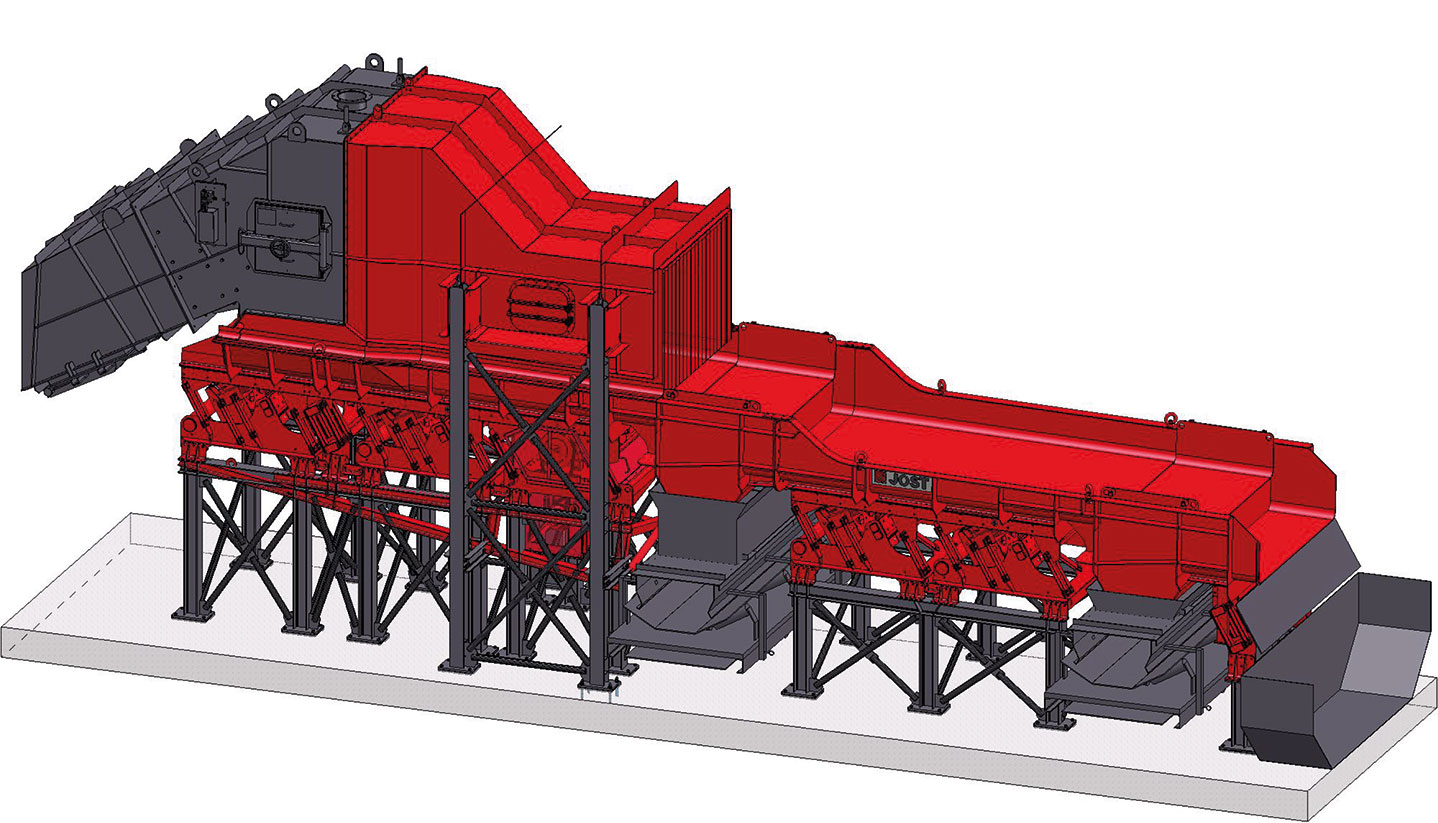

BPS/JOEST ASR processing plants for the USA

BPS – Best Process Solutions, Inc. and their German partner JOEST are supplying a complete processing system in the USA for the recovery of fine metal with a grain size smaller than 12 mm…

Heating Up International Cooperation

JOEST US was approached by one of the world’s leading scrap aluminum companies to provide ideas…

Perfect separation of Rubber and Textile with the JOEST Air Separation Table

JOEST Solutions for Used Tires Recycling…

Newmont Gold – successful start-up

During 2012, Newmont Mining commissioned a 4.3 m-wide (14 ft) by 7.3 m (23 ft) long double-deck banana screen at its Phoenix operation at Battle Mountain, Nevada…

Start-up of Europe´s biggest vibrating machine

Over Easter JOEST delivered and mounted Europe’s biggest vibrating machine – a casting cooler with a capacity of 55 t/h automotive castings for one of the biggest customer foundries in Germany…

JOEST delivered one of the biggest vibrating fluidized bed dryer in company history

JOEST is a worldwide leading supplier of vibration technology.