At JOEST, we take pride in optimizing our customers’ production with innovative technologies and customized solutions. A recent example is our collaboration with HYDROTEC Technologies AG, an internationally operating company with over 50 years of experience and a clear vision: to continuously improve.

Sorting Technology

#cooling, #sorting & #batchloading

JOEST delivered several types of machines from its product portfolio for castings for a customer‘s complete system. To simplify and enhance the original process of storing casting parts in boxes for the cooling process, a JOEST Casting Cooler was installed downstream the existing shakeout.

JOEST Shakeout with Counter Frame

For a client from the foundry industry based in Croatia, JOEST designed and manufactured a Shakeout. Its frequency and oscillation angle can be adjusted electronically, and this design includes a downstream feeder with dual-lane discharge. The machines were delivered to Croatia during the second fiscal quarter of 2021. Commissioning is performed and overseen by JOEST and is planned for this summer. The client ‘s demand was to provide a reliable Shakeout that could handle a large spectrum of parts whilst maintaining a small form factor due to space limitations on site. The machine should separate as much sand as possible without damaging the casts made of gray cast iron and spheroidal graphite iron. The client’s molding plant type HWS EFA-SD 5 with molding boxes of 1000x920x650 mm produces a maximum of 80 molds per hour. Roughly 2000 different parts are produced, the heaviest weighing 300 kg.

GOODBYE IFAT 2022! EN

We are looking back on a successful exhibition and informative days and would like to thank all of our visitors. We were able to have many interesting meetings and discussions, made a lot of new contacts and could present our Flip-Flow Screens of the new OSCILLA Family and the new J-Flow Air Separator very successfully. A great success overall! Thanks to the organization and the great #JOESTeam. We are already looking forward to the next IFAT in 2024!

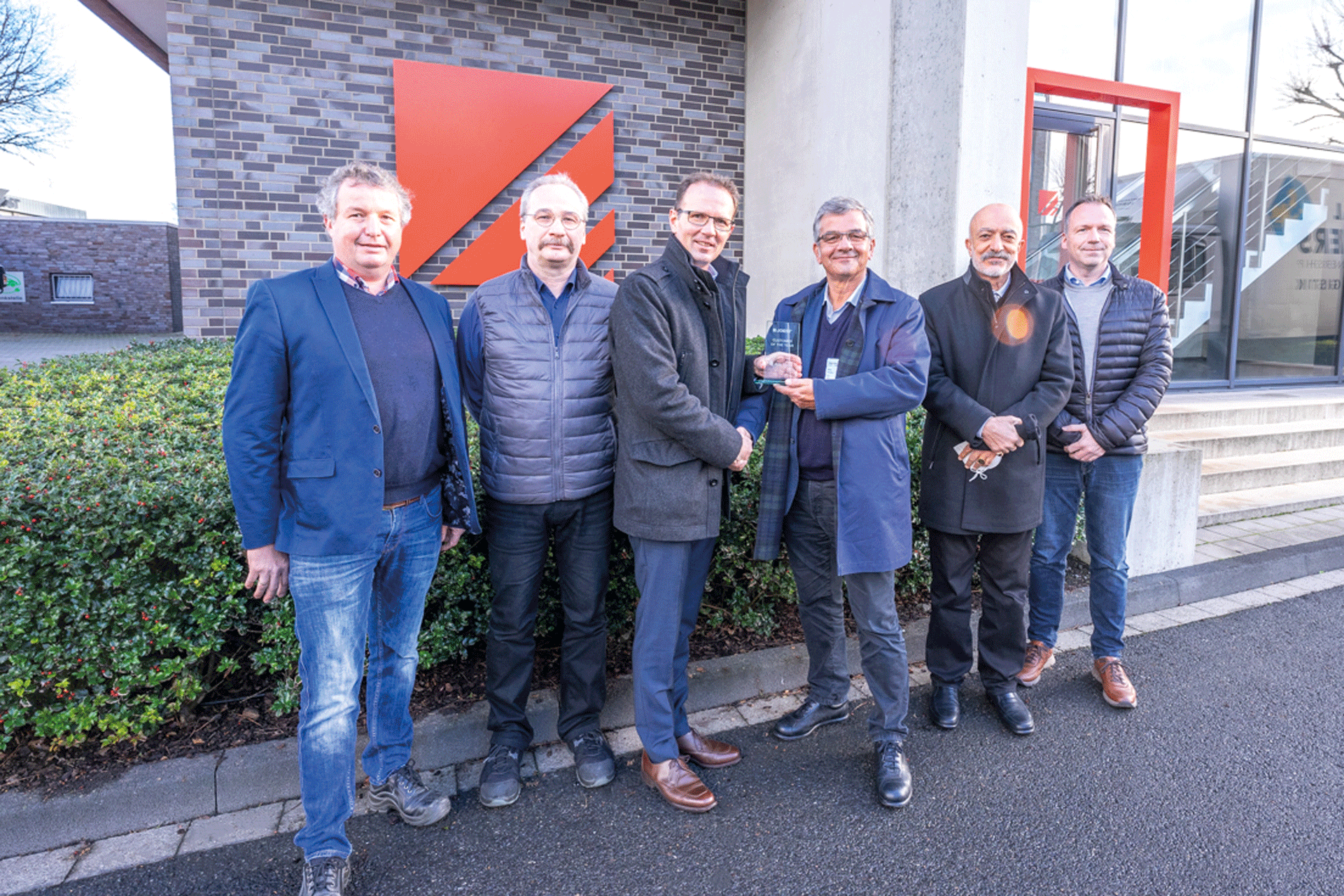

Customer of the Year EN

Atik Metal, one of the largest and most modern foundries in Turkey, producing mainly for export, makes a new investment. The Project includes two new HWS molding plants, the according Eirich sand processing with vacuum mixers and two custom shakeouts followed by manipulator supported cast processing technology. Als Trennrinnen kommen 2×2 Trennrinnen mit elektronischer Schwingparametereinstellmöglichkeit zum Einsatz. Empfindliche Gussteile, die für die Behandlung auf einer Trennrinne nicht geeignet sind, können per Manipulator auf eine parallel verlaufende Softhandlingstrecke übersetzt werden. So werden Oberflächenschäden vermieden. Auf der nachgeschalteten Lese- und Sortierrinne wird mittels Manipulator Kreislaufmaterial vom Gussteil getrennt und dann auf eine Hängebahnstrahlanlage transferiert.

Automatic feed systems for welding studs and flange nuts

JOEST manufactured two automaticfeed systems to convey, sort and feedwelding studs and flange nuts. Thesystems are built up of an overheadconveyor with a link chain, a storage container, a linear feeder and a workpiece recirculation. The workpieces are provided manually in a storage container with an effective volume of 320 liters. The container has a steel design and is lined with PU plates. It also features a filling level indicator. The parts are presorted by workpiece specific carrier rails, conveyed upwards and fed into a linear feeder. The linear feeder is equipped with two parallel sorting feeders. On these feed-ers, alignment mechanisms force the workpieces into the correct orientation. Excess or falsely orientated parts are rejected by the linear feeder and are recirculated to the storage container. The sorting feeders are equipped with pneumatic deflectors to prevent the magazine from overflowing and to control the feeding lane in case a screw is left out.

J-Flow Air Separator from JOEST

What do you need to achieve higher precision and purity in metal recycling? With the innovation of the J-Flow by JOEST, the answer is simple: Not a lot. The new compact Air Separator proves that for simple applications, machine size and investment costs can be significantly reduced – increasing simplicity and efficiency in the process. As a gravity separator, the J-Flow separates heavy parts from lightweight ones in an air stream. It is used for subsequent cleaning of metal fractions (ASR processing) to separate foils, fab-rics, lint, foam, Styrofoam and other light materials without losing to much metal. The operational grain sizes for the process are between 10 and 120 mm and long parts up to 300 mm.

JOEST Shakeout with electronically adjustable oscillation parameters

For a client from the foundry industry based in Croatia, JOEST designed and manufactured a Shakeout. Its frequency and oscillation angle can be adjusted electronically, and this design includes a downstream feeder with dual-lane discharge. The machines were delivered to Croatia during the second fiscal quarter of 2021. Commissioning is performed and overseen by JOEST and is planned for this summer. The client ‘s demand was to provide a reliable Shakeout that could handle a large spectrum of parts whilst maintaining a small form factor due to space limitations on site. The machine should separate as much sand as possible without damaging the casts made of GERMANY. Cast-/Sand-Shakeout after green sand forming line. JOEST Shakeout with electronically adjustable oscillation parameters gray cast iron and spheroidal graphite iron.

Process engineering solutions in glass recycling

Recycling is a growing market – especially in glass recycling new plants are currently arising or existing ones are updated and upgraded…

JOEST exhibits at “Letsrecycle Live” trade show in Great Britain

From the 22.-23. of May 2019, JOEST and PRM Waste Systems exhibited in Stoneleigh…

Handling of iron ore in a small space

In the middle of June 2017 JOEST delivered two hopper discharge feeder with very high process engineering and installation requirements…

Perfect separation of Rubber and Textile with the JOEST Air Separation Table

JOEST Solutions for Used Tires Recycling…