In recent years, JOEST Australia has increased its footprint within the Australian battery metals industry. JOEST Australia has delivered a package of 20 new machines comprising 18 different sizes and configurations, from dry scalping and sizing through to wet screening applications, to process the spodumene ore used in the conversion process to yield lithium hydroxide for the expanding battery industry. Due to the project‘s specific requirements, JOEST Australia personnel worked in close collaboration with the customer’s process design team to optimise the feeding and screening equipment used in this latest landmark greenfield project.

Thermal Processing Technology

JOEST group at POWTECH 2022

We look back on successful days at the POWTECH trade fair in Nuremberg. Interesting conversations, many new contacts and a good atmosphere. Our #JOESTteam is already looking forward to POWTECH 2023!

Drying system for extruded proteins

The food manufacturer Driessen Food Extrusion located in Deurne, Netherlands processes mixed, powdered, plant-based proteins to high quality ingredients for the food industry. In order to modernize their production and increase productivity, Driessen Food Extrusion is planning to build a new production line. JOEST received a contract last month to provide large parts of this new production line. For the processing of extruded proteins and production high quality coatings, the #JOESTeam will design and manufacture a complete drying plant. The planned drying system consists of a Fluidized Bed Dryer with processing-, heating-, cooling- and used-air systems as well as a Spiral Conveyor. The system will be delivered in spring 2023.

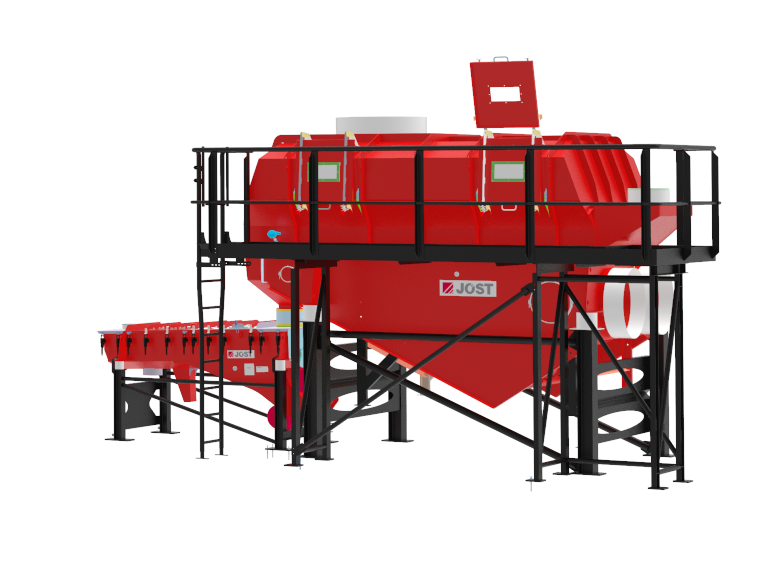

Cooling and screening of EPDM-granulates

Last year, JOEST got the order for the third cooling line of the Melos GmbH in Osnabrueck, a manufacturerof EPDM-granulates and cable compounds. The first order of this sequel was placed back in 2016. Melos is a leading manufacturer of plastics for sport- and playground surfaces. They use their know-how to develop custom solutions for various plastic applications including the cable industry and many more. The core of the plant is a JOEST Fluidized Bed Dryer, a Markus Dieckmann, Project Engineer, Melos GmbH GERMANY. Third order in a row for JOEST. Large plant for cooling and screening of EPDM-granulates processing and exhaust air system including pipelines, and a JOEST Feeder. For the demanded cooling of EPDMand EVA-granulates as well as PE-compounds, JOEST designed and manufactured a Fluidized Bed Dryer that is tailored to the application.

Oil recovery up to 95% with the Washing Centrifuge by GOESSLING

De-oiling, washing, cleaning and drying in a single machine…

100 m Conveying Cooler for forging party

Dr. Goessling Maschinenfabrik GmbH delivered a conveying system specifically optimized for the client…

Fully automated de-oiling, washing, cleaning and drying of screws – within a single system

Maximal throughput when de-oiling and cleaning screws or small parts of various dimensions…

JOEST receives third order in a row

JOEST was awarded another contract to manufacture another large plant for screening and cooling of granulate material. The client is Melos GmbH, the specialist in EPDM-Granulat and Cable Compounds, based in Melle by Osnabrueck.

Process engineering solutions in glass recycling

Recycling is a growing market – especially in glass recycling new plants are currently arising or existing ones are updated and upgraded…

Cast iron sewer parts are cooled on 27 meter casting cooler

Cast iron parts are cooled from 550°C to 80°C on a vibrating machine. A client from Poland placed an order with JOEST to manufacture a casting cooler for cast iron sewer parts…

JOEST displays on POWTECH again

For the first time, the in-house brand DIETERLE® reinforces the trade show stand. Exiting exhibits attracted many visitors to the 72 m² JOEST stand at the POWTECH 2019…

First JOEST drying plant for diatomite in Australia

Australia JOEST assists in the assembly of a complete drying plant with classification for an Australian agricultural company…

HEXION excited from JOEST quality

Great teamwork – satisfied customer. Hexion GmbH, one of the world’s leading specialty chemicals companies, ordered a JOEST cooling conveyor to cool duroplastic molding compound…

Hot, hotter, JOEST!

JOEST supplies a spiral elevator for active carbon with a feed temperature of up to 300° C. In June 2018, JOEST sold an approximately 7 meter high spiral conveyor to a customer in the Netherlands…

Smart foundry in Turkey equipped with JOEST machines

JOEST delivered the complete vibrating machines to Trakya Dokum’s new smart foundry in Turkey…

Fluidized bed dryer for Polish end customer

JOEST received another order for a fluidized bed dryer for the thermal processing of mineral granulates…

Start-up of Europe´s biggest vibrating machine

Over Easter JOEST delivered and mounted Europe’s biggest vibrating machine – a casting cooler with a capacity of 55 t/h automotive castings for one of the biggest customer foundries in Germany…

JOEST Casting cooler

For a foundry in Asia JOEST manufactured a casting cooler with a width of 1,6 m and a total length of 45 m. The machine …

JOEST delivered one of the biggest vibrating fluidized bed dryer in company history

JOEST is a worldwide leading supplier of vibration technology.