RECYCLING

Unique feature makes JOEST the favourite in waste incineration

At the end of 2017, JOEST will supply four resonance conveyors to Hitachi for a waste-to-energy plant.

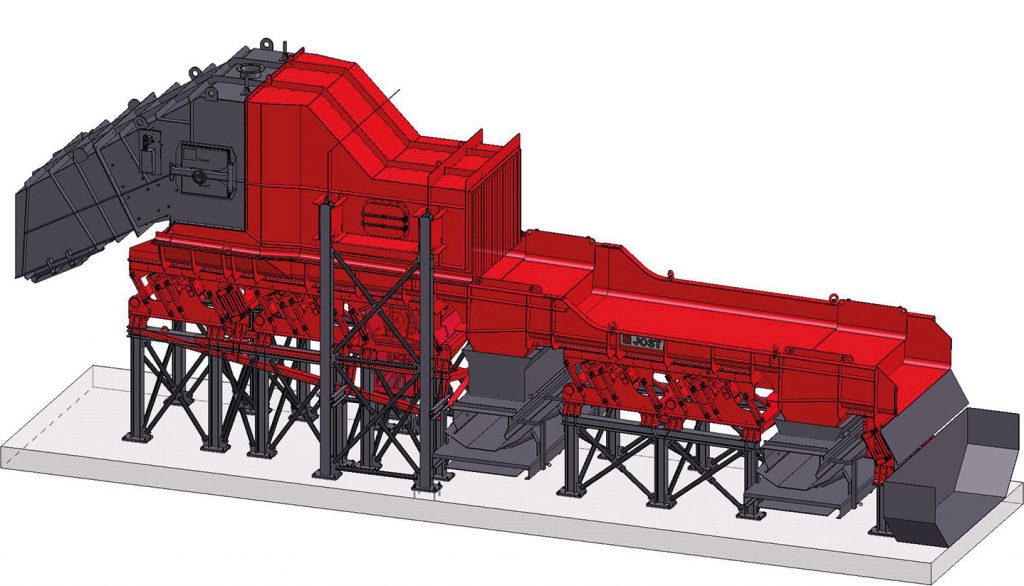

In the north of England, an existing power plant is currently being expanded to include a second waste incineration plant for household and industrial waste. Mass-compensated resonance conveyors (FSM) from JOEST will be used to separate the coarse and fine waste slag.

The expanded Ferrybridge waste-to-energy plant near Manchester will incinerate around 566,000 tons of waste each year and convert it into energy. To transport the waste, four FSMs from JOEST are being installed to carry out the initial separation of the coarse and fine waste slag in order to protect the conveyor belts.

Two conveyor belts, which are stored below the conveyors, can be fed by the two split grates that are installed in each resonance conveyor. Since the belts do not run in parallel due to the distribution of the waste, it was necessary to ensure that only one is constantly being fed, and that the changeover between the two conveyor belts can take place within a very short time. For this reason, JOEST has developed special cover plates that make it possible to complete the changeover on all four machines with a system downtime of just 20 minutes.

During the development phase, particular attention was paid to the high demands placed on the welding technology, as well as the painting and coating of the system. In terms of the welding results, it was important to ensure a robust design, as sometimes larger parts are transported on the resonance conveyor. The waste slag is also chemically aggressive, which is why it was essential to apply a durable coating. The on-site conditions presented an additional problem — it was not possible to attach the motor and crank drive in series underneath the machine due to a lack of space. As a result, the machine had to be redesigned so that the motor could be attached vertically to the machine, underneath the drive unit.

When it comes to mass-compensated resonance conveyors, JOEST has an absolute unique selling point. Its machines are able to transport the waste slag and separate the coarse and fine material while conducting only a minimum of their vibrations into the ground. Many customers of the JOEST group have depended on this feature for several decades.

Weitere Beiträge

As part of the JOEST group, MOGENSEN has been a trusted provider of high-performance screening and sorting technologies for many years. The new website now showcases this expertise more clearly and with a modern touch.

On International Women’s Day, we celebrated the great women in our company who have made a significant contribution every day with their commitment, expertise and passion. Their efforts have been a driving force behind our success and an inspiration to us all.

JOEST South Africa was commissioned to manufacture and supply replacement vibrating feeders for a critical power generation facility. The new units are designed to replace equipment that had been in operation for over 20 years, ensuring the continued reliability and efficiency of the plant.

MOGENSEN joins China’s food security project as an official supplier, supporting the nation’s plans to strengthen domestic grain production capabilities. The appointment by COFCO, China’s largest state-owned agricultural company, includes the deployment of multiple precision screening systems for processing rice, wheat and soybeans, among other grains. This long-term initiative is in line with China’s new food security law, which went into effect on June 1, 2024.