MDS-SERIES

LIFTING/TIPPING

MDS-Series

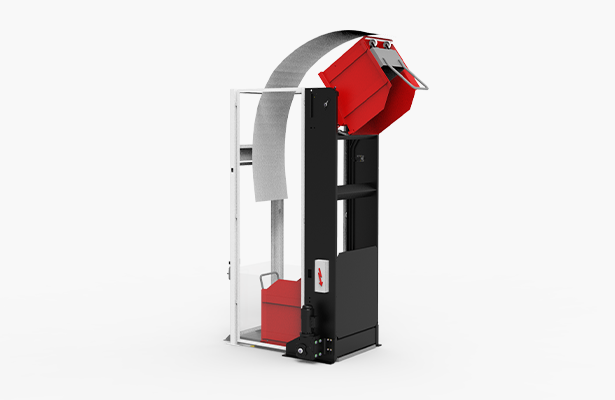

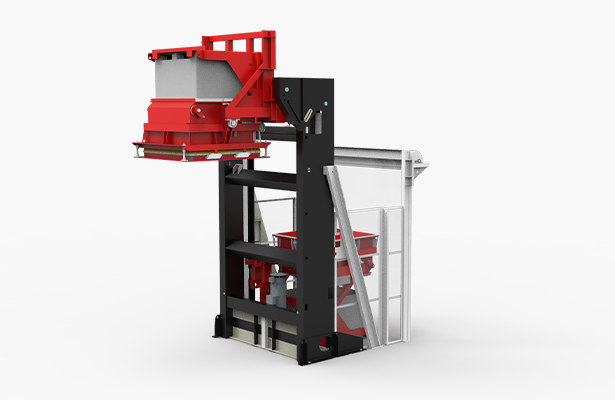

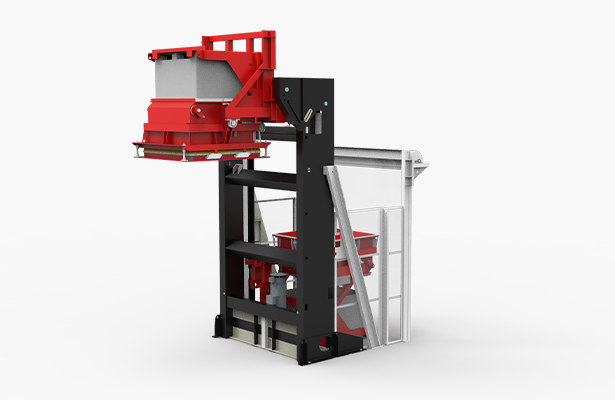

JOEST® lifting/tipping equipment of the MDS series are designed as 2-stand equipment. Generous dimensions in the construction method offer high power reserves, safety and longevity. The solid construction is particularly suitable for rough operation in foundries or in recycling plants. Stacking containers, heavy duty containers and foundry containers can easily be lifted and tipped with this model. The use of a redundant chain system with increased breaking load is also relevant with this robust design.

The heavy design can achieve tipping heights of 1,400 mm to 12,000 mm with load-bearing capacity of up to 3000 kg. The peculiarity of this design lies in the possibility to increase the tipping angle to 180 degrees, this facilitates the emptying of the parts of the beaded containers. It is also possible to make the series movable by using a chassis. Thus, you can do more than just feeding a subsequent system.

The advantages of the MDS series include not only the reduction in energy expenditure, but also the time savings which an automatic tipping process provides. Various optional equipment help to optimize the tipping process and to provide the bulk material as best as possible for the subsequent process. Thus, a sealing cap can be used in the load-handling equipment for a noise-reducing part-discharge. Furthermore, there is the possibility of tipping several types of containers with different dimensions with only one tipping equipment. For this purpose, the Dieterle brand offers a comprehensive and flexible design of the container safety system. The fully automatic container safety equipment is specially adapted to the containers used in the design.

Various linings for the load-handling equipment are available, these provide additional wear protection, serve the noise insulation or can contribute to an optimized material flow. In combination with conveyor systems an automatic feed and return of the containers is made possible. The operationally safe tipping is adapted to your requirements through personal protection equipment. The MDS series is wired to a terminal box or is available complete with its own electrical control with various functions and operating modes for automated lifting and tipping.

The scope of application of the MDS series ranges from metallurgy, automotive, to surface treatment and heat treatment, stone and earth, to chemical and plastics industries. The material design is determined depending on the application. Thus, in addition to the design in normal steel, versions in stainless steel or mixed constructions are also possible. Likewise, requirements in a potentially explosive atmosphere (ATEX) can be implemented.

- Closing lid in the bulk of the load carrier for gentle product transfer

- Various linings of the load carrier are available, these offer additional wear protection, serve for noise insulation or can contribute to an optimized material discharge

- Hydraulic container safety for different container dimensions

THE MDS-Series

Read more about the MDS series, different designs and options here.

If you have any questions or are interested, please contact us directly!

BENEFITS

- Heavy construction for rough operation

- 2 pieces of load chainsand 2 pieces of safety chains each with 250,000 N breaking load

INDIVIDUAL

Options and Accessories

All lifting and tipping machines have a variety of different options and accessories to choose from. For example, you can be equipped with automatic chain lubrication, special coating in almost any RAL tone, container weighing, locking bolt securing to fix the load carrier, maintenance platforms on the machine head, PLC control, level monitoring, etc.

MD-SERIES

Designs

CONATCT FORM

Write to us!

Contact us quickly and easily via the following form. We will get back to you as soon as possible!

Alternatively, you can reach our head office at +49 2590

98-0.