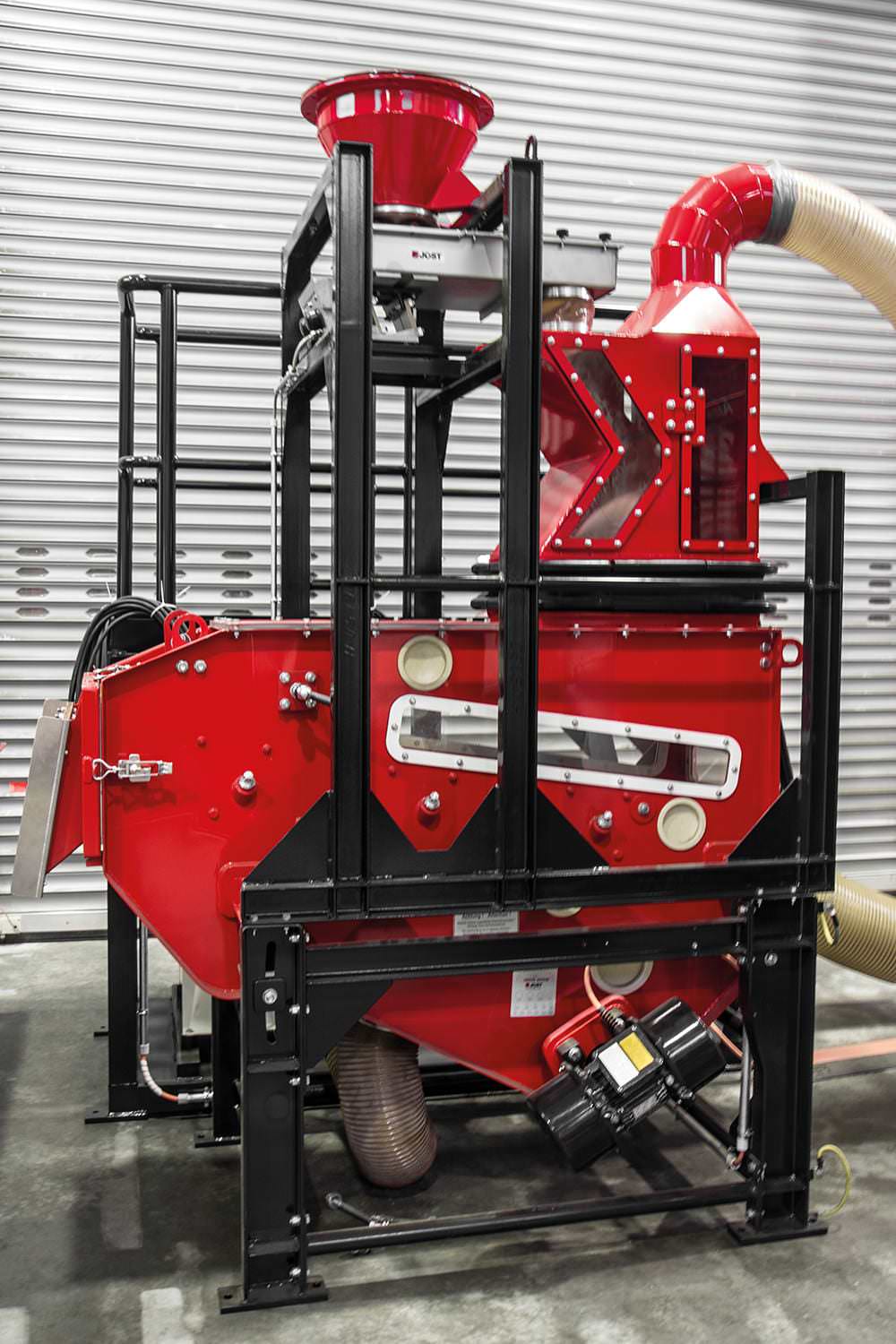

The K-Separator is placed on top of the aspiration cover of the JOEST separation table to pre-separate very light products. The feeding material is conveyed by a vibration or dosing feeder to the K-Separator. The vibration feeder spreads the product over the whole width of the separator and prevents at the same time that additional air enters the separator by using rubber curtains.

The product mixture is led into the separation zone and will be separated into heavy and light fractions by cross flow and counter current flow separation process. The ultra light fraction is exhausted at an aspiration socket. The heavy fraction gets in the separation table and will again be separated into heavy and light fraction (see description of separation table). The process air of the separation table is also used for the sifting, adjustments can be made by a flap inside the K-Separator.

Vibration feeder or dosing feeder for material intake (necessary)

Cyclone and/or filter installation with aspiration fan for the aspiration air of separator and separation table (necessary)

Please refer Separation Table

Additional height of the K-Sifter = 600 mm

Advantages

K-Sifter

Possible three-component-sorting via combination of K-Separator and separation table

No further process air necessary. The air of the separation table is used as process air for the separator

Very low construction hight of only 600 mm necessary

Low costs in comparison to a standard air separation installation

Bypass regulation to control the required separator air coming from the separation table is installed inside the K-Separator

Applications

Secondary Raw Materials - Recycling

Related Products

Discover more

to know more?