Reclaimed sand attrition units and sand transportation troughs for leading German automobile manufacturer

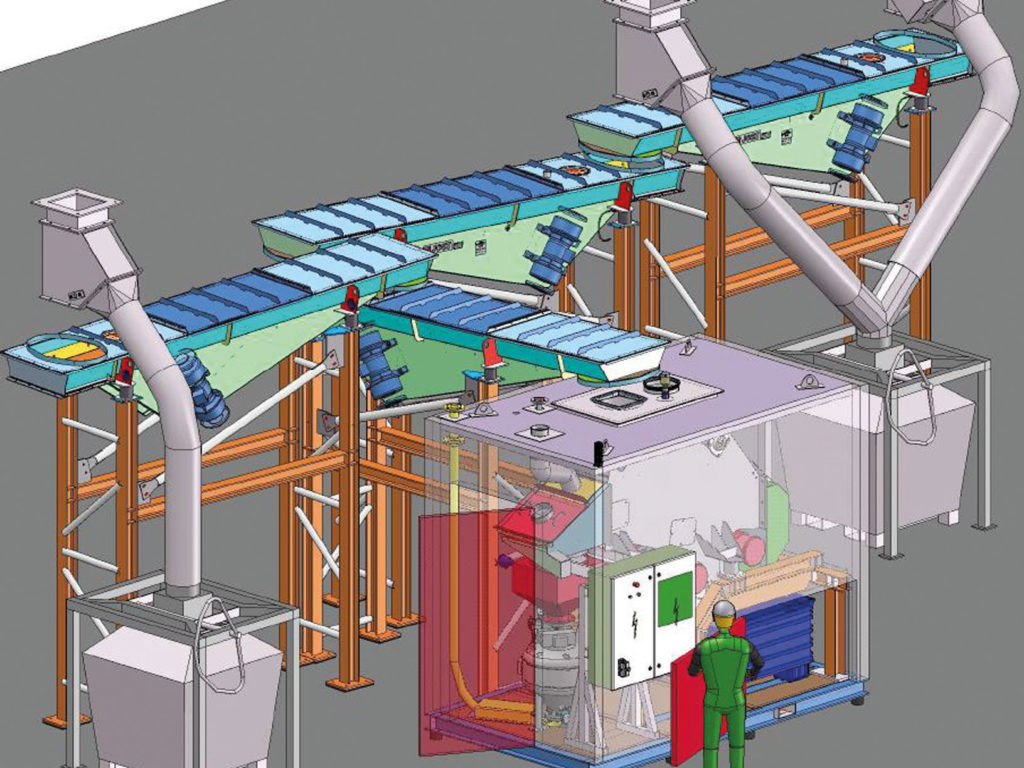

JOEST receives an order subdivided into multiple stages from a leading German automobile manufacturer, the first of which includes five modularly designed reclaimed sand attrition islands for inorganically bonded core sand from an aluminium foundry.

In order to manufacture complex cast iron parts for automobile engines and parts for electric cars from aluminium, a commonly applied process is the gravity die casting process. In the process, the outer contours of the cast iron part is manufactures in two parts as a permanent mould. The interior of the mould consists of chemically bonded core sand. When the cast iron part solidifies, the core sand residue is extracted using powerful mechanical oscillations.

The accumulated core sand is collected to so called “island points” using sand conveying troughs, which are located at multiple extraction points in the ceiling. The sand is then grinded be the reclaimed sand attrition units. The sand that is now broken down into single grains is now conveyed through a pipeline to a collection silo by pneumatic thrust conveyor using pressured air.

The delivery of the first stage contains five reclaimed sand attrition units in total and is scheduled for the end of 2019. JOEST says thank you for the trust and is looking forward to a successful implementation.