GOESSLING Conveying Technology for stamping scrap in chassis manufacturing.

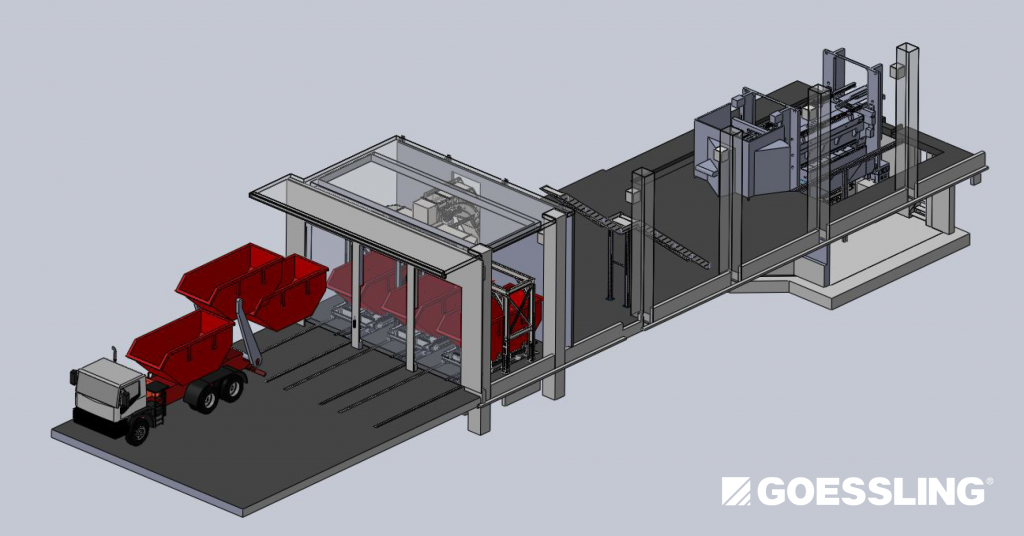

This year in September, GOESSLING delivered a customized conveying solution to a long-term client that once again relied on the high quality and positive user experience of GOESSLING. When manufacturing chassis parts, stamping scrap occurs beneath the stamping press. These scrap parts must be disposed in containers. Using their experience in conveying technology, GOESSLING was able to offer the client a robust solution with excellent service.

The special challenge of this project was that the stamping scrap is charged over a special chute system in the basement onto a Double-Z-Conveyor with an effective widt of 625 mm. The scrap is then transferred on a reservable conveyor with the same effective width. At the the transitions, the reservable conveyor has pivoting chutes. The both pivoting slides enable the oily scraps to be distributed into three displaceable containers.

The conveying system, made from aluminum, steel, stainless-steel and galvanized sheet metal is low-maintenance and is delivered in an oil-tight configuration. Stamping scrap can be conveyed at a throughput of four to six tons per hour. Commissioning is scheduled by the GOESSLING-Team for September.